For Powder metal sintering and ferrite sintering, the furnace which material passes through is a reduced atmosphere free of oxygen. The Kanthal® Super ER grade of heating element is a top choice amongst manufacturers because it provides high furnace temperatures (over 1250°C), horizontal installation in the furnace roof, and no abnormal surface oxidation.

Horizontally installed ER elements can be recommended for applications both running in normal atmospheres as well as powder metallurgy applications or in applications with controlled atmospheres as described above.

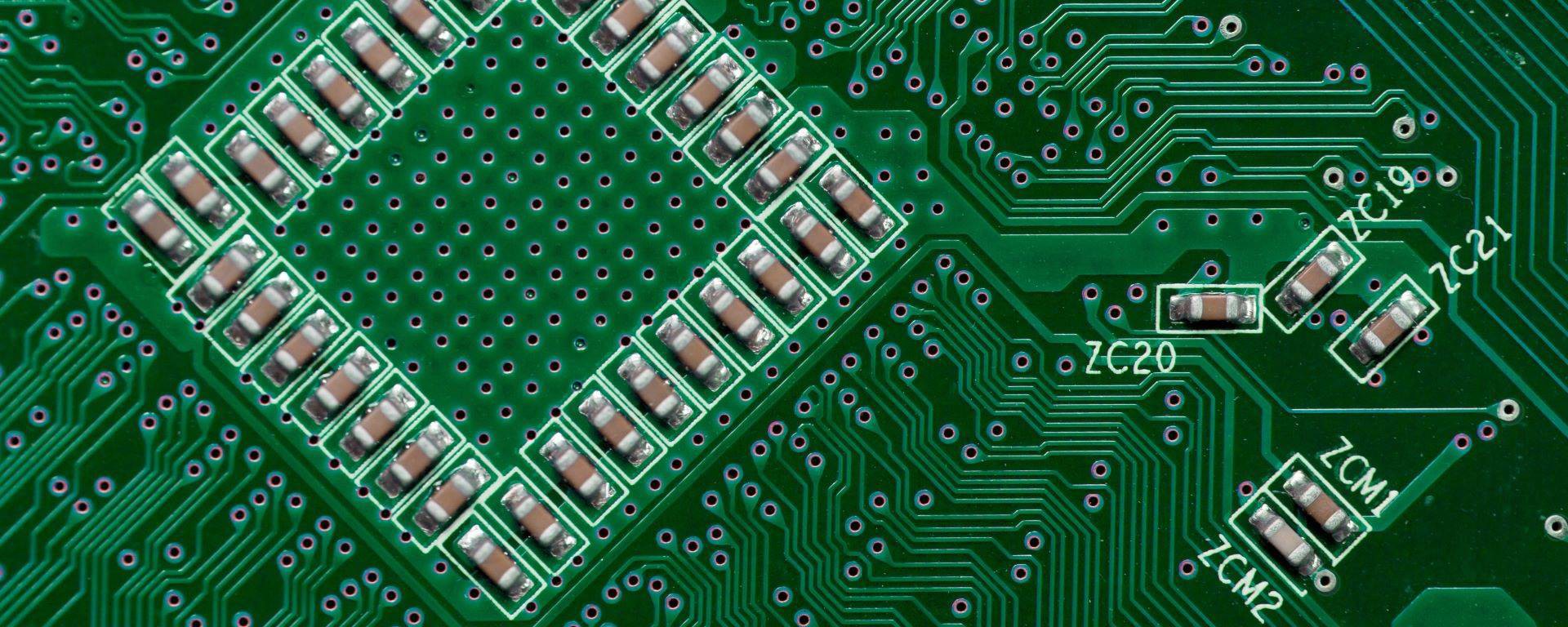

In addition, we offer several other grades suitable for casting binding and sintering. Contact our specialist to see if our offering fits your MLCC processes.

Connected products

Here you can find the Kanthal product offering