Content:

Ribbon

Rods

Other resistance alloys - Cuprothal®

RESISTANCE HEATING ALLOYS – KANTHAL®, ALKROTHAL®, NIKROTHAL® AND NIFETHAL®

Wire

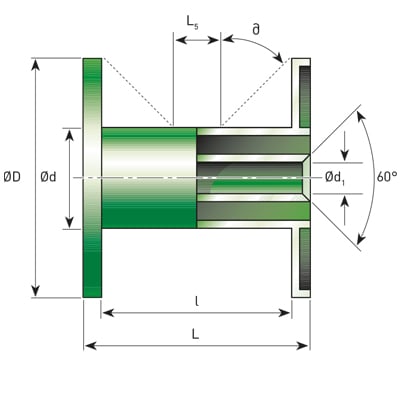

Spool (B 1, B 2, B 4).Wire of ≤1.63 mm (0.064 in) is delivered on spools, such as shown in the figure. Only one length of wire is wound on each spool.

Spool (B 1, B 2, B 4).Wire of ≤1.63 mm (0.064 in) is delivered on spools, such as shown in the figure. Only one length of wire is wound on each spool.

Wire sizes between 0.40 and 1.63 mm (0.016–0.064 in) can be supplied in round pail packs (drums) such as shown in the table below.

Wire sizes >1.65 mm (0.065 in) is normally supplied incoils with an inner diameter of approx. 500–600 mm (19.7–23.6 in).

Types of wire spools

| Spool | Tare | Spool measurements | Wire diameter | Capacity approx. | ||||||||||||

| No. | g | lb | D mm | D in | D mm | D in | D1 mm | D1 in | L mm | L in | L mm | L in | mm | in | kg | Ib |

| B 1 | 100 | 0.22 | 75 | 2.95 | 40 | 1.57 | 16 | 0.63 | 120 | 4.72 | 100 | 3.94 | 0.10 – 0.19 | 0.004 – 0.007 | 1 | 2.2 |

| B 2 | 115 | 0.25 | 90 | 3.54 | 40 | 1.57 | 16 | 0.63 | 120 | 4.72 | 100 | 3.94 | 0.20 – 0.24 | 0.008 – 0.009 | 2 | 4.4 |

| B 4 | 180 | 0.40 | 120 | 4.72 | 50 | 1.97 | 16 | 0.63 | 120 | 4.72 | 100 | 3.94 | 0.25 –1.00 | 0.010 – 0.039 | 4 | 8.8 |

| DIN 200 | 600 | 1.32 | 200 | 7.87 | 125 | 4.92 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 0.16 –1.20 | 0.006 – 0.047 | 10 | 22.0 |

| DIN 250 | 1050 | 2.31 | 250 | 9.84 | 160 | 6.30 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 0.30 –1.63 | 0.012 – 0.064 | 20 | 44.1 |

| DIN 355 | 1850 | 4.08 | 355 | 13.98 | 224 | 8.82 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 0.50 –1.63 | 0.022 – 0.064 | 40 | 88.2 |

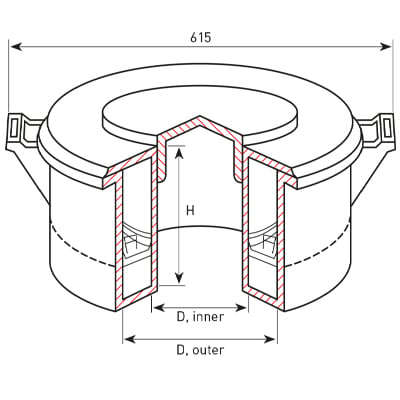

Pail pack.

Pail pack.

Types of wire pails (drum pack)

| Pail | Tare | Pail measurements | Wire diameter | Capacity approx. | |||||||||

| No. | g | lb | D, outer mm | in | D, inner mm | in | Height mm | in | Material | mm | in | kg | ib |

| P 50 | 2600 | 5.7 | 508 | 20.0 | 330 | 13.0 | 150 | 5.9 | plastic | 0.40 –1.63 | 0.016 – 0.064 | 33 | 73 |

| P 100 | 3500 | 7.7 | 508 | 20.0 | 330 | 13.0 | 250 | 9.8 | plastic | 0.40 –1.63 | 0.016 – 0.064 | 50 | 110 |

| P 200 | 8500 | 18.7 | 500 | 19.7 | 300 | 11.8 | 520 | 20.5 | cardboard | 0.80 –1.63 | 0.031 – 0.064 | 160 –240 | 352 – 529 |

| P 350 | 10000 | 22.0 | 500 | 19.7 | 300 | 11.8 | 820 | 32.3 | cardboard | 0.80 –1.63 | 0.031 – 0.064 | 250 –400 | 551 – 882 |

Ribbon

Ribbon is normally supplied on DIN 125 spools. Sizes of section ≥0.3 mm2 (0.0005 in2) are wound on DIN 100 spools. If requested, the smallest sizes can be supplied on DIN 80 spools.

Rods

Available shaved or unshaved depending on the alloy.

Types of ribbon spools

| Spool | Tare | Spool measurements | Capacity Kanthal® | Capacity Nikrothal® | ||||||||||||

| No. | g | Ib | D mm | D in | D mm | D in | D1 mm | D1 in | L mm | L in | L mm | L in | kg | Ib | kg | Ib |

| DIN 80 | 70 | 0.15 | 80 | 3.15 | 50 | 1.97 | 16 | 0.63 | 80 | 3.15 | 64 | 2.52 | 0.7 | 1.5 | 0.8 | 1.8 |

| DIN 100 | 125 | 0.28 | 100 | 3.94 | 63 | 2.48 | 16 | 0.63 | 100 | 3.94 | 80 | 3.15 | 1.5 | 3.3 | 1.9 | 4.2 |

| DIN 125 | 200 | 0.44 | 125 | 4.92 | 80 | 3.15 | 16 | 0.63 | 125 | 4.92 | 100 | 3.94 | 3 | 6.6 | 3.5 | 7.7 |

| DIN 200 | 600 | 1.32 | 200 | 7.87 | 125 | 4.92 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 12 | 26.5 | 13 | 28.7 |

OTHER RESISTANCE ALLOYS – CUPROTHAL®

The wire is normally packed as shown below. Wire and ribbon can also be specially packed to individual requirements. To provide additional protection to the materials, spools are wrapped with plastic film or closed in plastic boxes.

WIRE

Wire ≤1.63 mm (0.064 in) is available on spools. At the request of the customer, wire can also be supplied in pails.

Wire dimensions from 1.63 to 6.0 mm (0.064– 0.236 in) are available in coils. The inner diameter of the coil is 500 to 600 mm (19.7–23.6 in) depending on the alloy type and the diameter.

RODS

Available as shaved or not shaved depending on the alloy. Wire from 2.00 mm up to 8.0 mm (0.079–0.031 in) can be straightened in random or fixed lengths.

Straight lengths are supplied in bundles.

Types of spools for Cuprothal®

| Spool | Tare | Spool measurements, mm (in) | Wire diameter | Nominal wire weight | ||||||||||||

| No. | g (lb) | Ib | D mm | D in | D1 mm | D1 in | D2 mm | D2 in | L mm | L in | L mm | L in | mm | in | kg | Ib |

| DIN 500 | 7650 | 16.9 | 500 | 19.7 | 315 | 12.4 | 36 | 1.42 | 250 | 9.84 | 189 | 7.44 | 0.80 – 1.40 | 0.031 – 0.05 | 90 | 198.4 |

| DIN 355 | 2380 | 5.2 | 355 | 13.98 | 224 | 8.8 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 0.40 – 1.40 | 0.016 – 0.05 | 40 | 88.2 |

| DIN 250 | 1050 | 2.3 | 250 | 9.84 | 160 | 6.30 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 0.25 – 1.00 | 0.010 – 0.039 | 20 | 44.1 |

| DIN 200 | 580 | 1.3 | 200 | 7.87 | 125 | 4.92 | 36 | 1.42 | 200 | 7.87 | 160 | 6.30 | 0.25 – 0.80 | 0.010 – 0.031 | 10 | 22.0 |

| DIN 160 | 350 | 0.77 | 160 | 6.30 | 100 | 3.94 | 22 | 0.87 | 160 | 2.36 | 128 | 5.04 | 0.20 – 0.80 | 0.008 – 0.031 | 6 | 13.2 |

| DIN 125 | 200 | 0.44 | 125 | 4.92 | 80 | 3.15 | 16 | 0.63 | 125 | 4.92 | 100 | 3.94 | 0.15 – 0.80 | 0.006 – 0.031 | 3 | 6.6 |

| DIN 100 | 120 | 0.26 | 100 | 3.94 | 63 | 2.48 | 16 | 0.63 | 100 | 3.94 | 80 | 3.15 | 0.127 – 0.25 | 0.005 – 0.010 | 1.5 | 3.3 |

| DIN 80 | 60 | 0.13 | 80 | 3.15 | 50 | 1.97 | 16 | 0.63 | 80 | 3.15 | 64 | 2.52 | 0.127 – 0.25 | 0.005 – 0.010 | 0.5 | 1.1 |