Content:

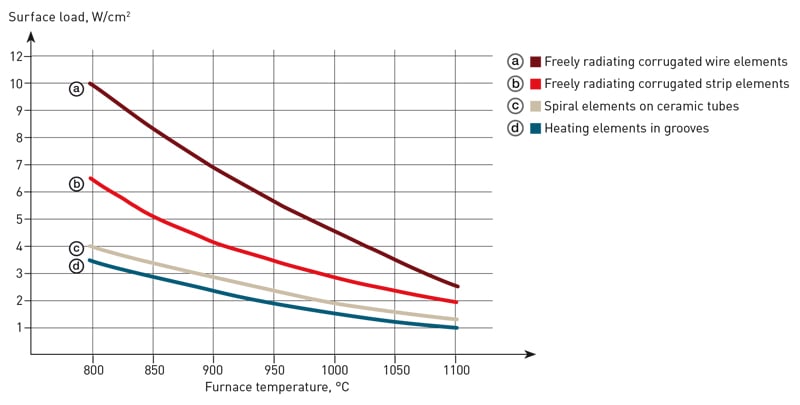

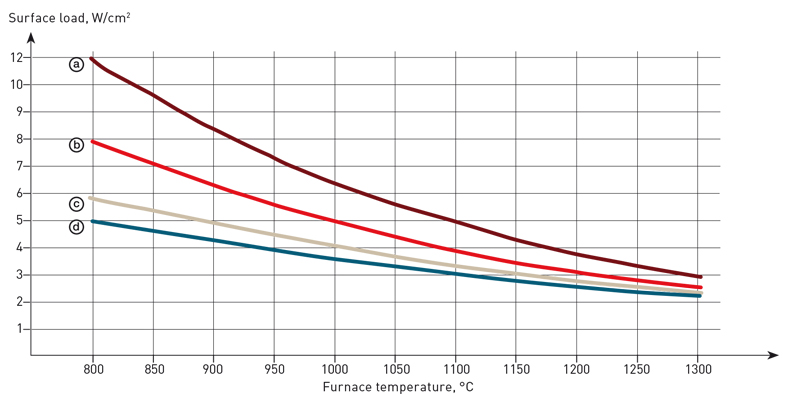

Coil elements on ceramic tubes can be loaded higher than coil elements in grooves. The values in the diagrams on page 9 are given for the following design conditions:

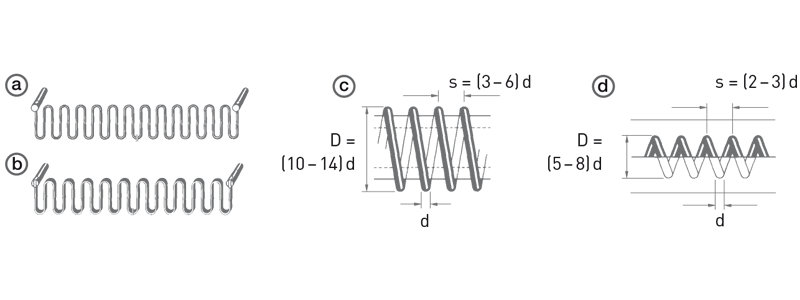

Element types A (heavy wire) and B (strip):

Strip thickness minimum 2.5 mm. Wire diameter minimum 5 mm. Pitch minimum 50 mm at maximum loop length and maximum surface load.

Maximum recommended loop lenght:

| < 900°C | 300 mm |

| 1000°C | 250 mm |

| 1100°C | 200 mm |

| 1200°C | 150 mm |

| 1300°C | 100 mm |

For finer wire diameters and smaller strip thicknesses lower surface loads and shorter loop lengths must be chosen to avoid element deformation and subsequent shorter element life.

Element type C:

Wire element on ceramic tube. Wire diameter minimum 3 mm.

Element type D:

Wire and strip element in grooves. Wire diameter minimum 3 mm, strip thickness minimum 2mm.

Note: The diagrams are valid for thyristor control. For on-off control lower surface loads should be chosen (about - 20%).

Note: The diagrams are valid for thyristor control. For on-off control lower surface loads should be chosen (about - 20%).

Maximum recommended surface loads for Kanthal® A-1, Kanthal® AF and Kanthal® APM alloys in industrial furnaces

Maximum recommended surace loads for Nikrothal® alloys in industrial furnaces