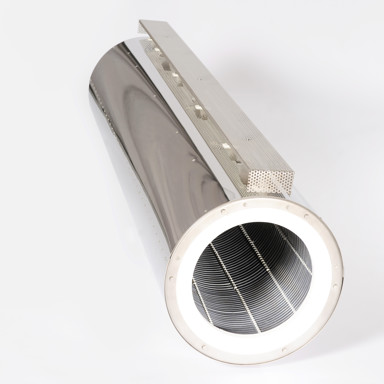

Light gauge diffusion cassettes

Light gauge cassettes are composed of light gauge wire that are formed into sinusoidal patterns or spring-type coils. Light gauge refers to the use of smaller diameter wire in the construction of cassettes. This configuration is crucial for precise control and response time of the diffusion process.

Information

Applications

LPCVD and Low-Temperature Applications: Used when precise control over low temperatures is required. Applications such as LPCVD; polysilicon, nitride, and low-temperature oxide. Atmospheric; H2 anneal, polyimide cure.

Fast Temperature Response Applications: Ideal for processes that demand rapid temperature changes.

Fast Cool Applications: Efficient in applications requiring quick cooling.

A typical low-mass heater consists of:

- Half-shell ceramic molds with embedded wire sinuation or spring coils.

- Ceramic mold backed with dry blanket fiber for designed insulation value and balanced compression.

- Tooled vacuum-formed ceramic vestibule end insulators.

- Varieties of thermocouple position clamps.

- Ceramic lead locks on internally bussed elements. Power blocks on externally bussed.

Characteristics

- Mid and light gauge wire sinuated, or spring coiled cold with precision machines.

- 25mm and 50mm typical sinuated bend patterns.

- SST or aluminum exterior casings.

- Low mass design for low temperatures and faster thermal response.

- White or black surface coating.

Related products

Other products that might interest you