Kanthal® alloys vs. Nikrothal® alloys

For the furnace user, using Kanthal® iron-chromium-aluminium (FeCrAl) alloys instead of nickel-chromium (NiCr) alloys results in less amount of material and also a longer element life, which mean considerable cost savings.

Information

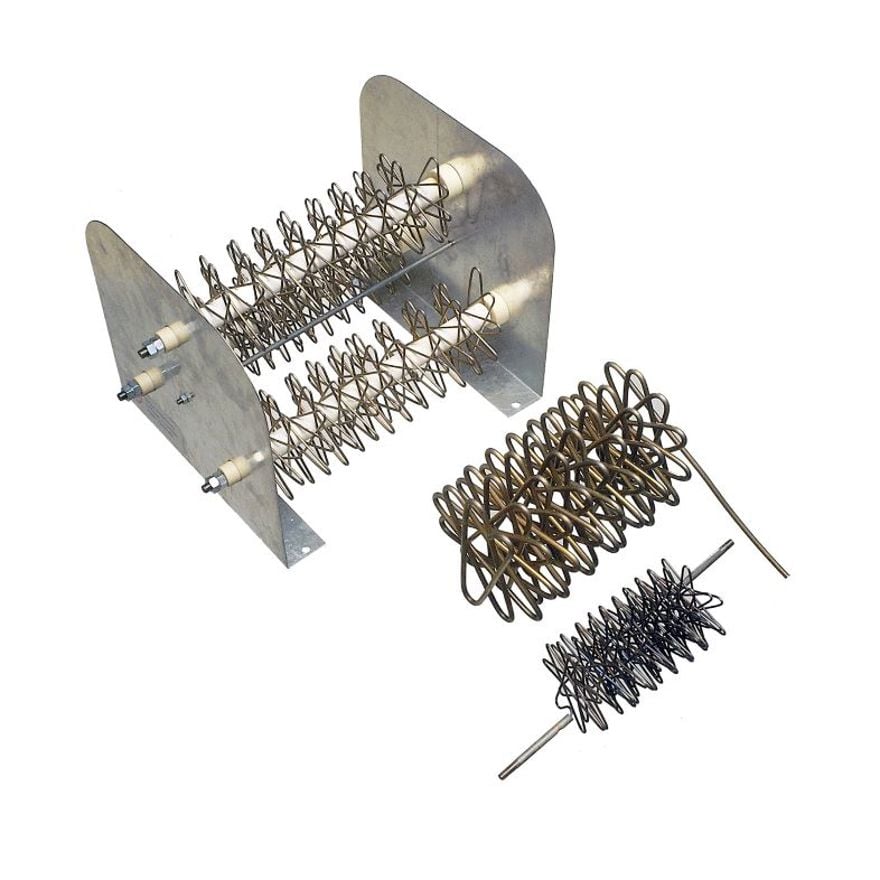

The table below shows an example of a 33% weight saving obtained by using a Kanthal® alloy instead of a Nikrothal® alloy. This lower element weight results in considerable cost savings, not only regarding element material but also support systems, because fewer suspension hooks are necessary.

| Nikrothal® alloy | Kanthal® alloy | |

|---|---|---|

| Furnace temperature °C (°F) | 1000 (1832) | 1000 (1832) |

| Element temperature °C (°F) | 1068 (1954) | 1106 (2022) |

| Hot resistance (Rw) | 3.61 | 3.61 |

| Temperature factor (Ct) | 1.05 | 1.06 |

| Cold resistance (R20) | 3.44 | 3.41 |

| Wire diameter mm (inch) | 5.5 (0.216) | 5.5 (0.216) |

| Surface load (W/cm2) | 3.09 | 3.98 |

| Wire length m (inch) 3 elements | 224.9 (8.82) | 174.6 (6.85) |

| Wire weight kg elements | 44.4 | 29.6 |

44.4-29.6/44.4 = 33% weight saving (based on the same wire diameter)