Kanthal® APM and Kanthal® APMT FeCrAl alloys

Kanthal® APM and Kanthal® APMT iron-chromium-aluminium (FeCrAl) alloys can be used at tube temperatures up to 1250°C (2282°F). They offer several advantages compared to other tube materials such as alumina, silicon carbide and nickel-chromium (NiCr) alloys.

Information

User benefits include superior resistance to, for example, carburization, thermal shock, sagging and distortion. This is due to the materials' excellent mechanical properties* and their capability of forming a dense and adherent oxide film that protects against corrosion and atmospheric attack. The service life of Kanthal® APM and Kanthal® APMT furnace tubes is often many times longer than that of nickel-chromium (NiCr) alloy-based tubes.

* Kanthal® APMT offers higher hot strength than Kanthal® APM which makes the grade even more resistant to sagging.

Characteristics

Kanthal® APM/APMT tubes have good form stability at high temperature. Kanthal® APM/APMT forms an excellent, non-scaling surface oxide, which gives good protection in most furnace environments, i.e. oxidizing, sulphurous and carburizing, as well as against deposits of carbon, ash, etc. The combination of excellent oxidation properties and form stability makes the alloy unique.

Typical applications for these radiant tubes are in electrically or gas fired furnaces such as continuous annealing and galvanizing furnaces, seal quench furnaces, holding furnaces and dosing furnaces in the aluminium, zinc, lead industries, thermocouple protection tubes, furnace muffles for sintering applications.

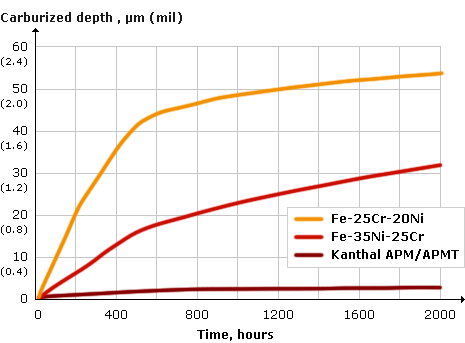

Comparison of carburization resistance

Comparison of carburization resistance

| Grade | Maximum temperature 1) | Rkm 10000 2) |

|---|---|---|

| Kanthal® APM | 1250°C (2280°F) | 0.9 |

| 1250°C (2280°F) | 3.5 |

shows recommended maximum tube temperature.

2) Creep rupture strength 10000 h MPa (N/mm2) at 1100°C (2010°F).