Dean McCabe, Technical Support Manager, Kanthal“Globar® is the result of an ongoing continuous development process, where our aim has been to produce a heating element that is more reliable and can help improve the overall cathode material production process,” says Dean McCabe, Technical Support Manager, Kanthal. “Demand for cathode material is rapidly increasing because of the growth of electric vehicles, and we want to help cathode manufacturers meet this demand.”

Dean McCabe, Technical Support Manager, Kanthal“Globar® is the result of an ongoing continuous development process, where our aim has been to produce a heating element that is more reliable and can help improve the overall cathode material production process,” says Dean McCabe, Technical Support Manager, Kanthal. “Demand for cathode material is rapidly increasing because of the growth of electric vehicles, and we want to help cathode manufacturers meet this demand.”

Attention to micro-details

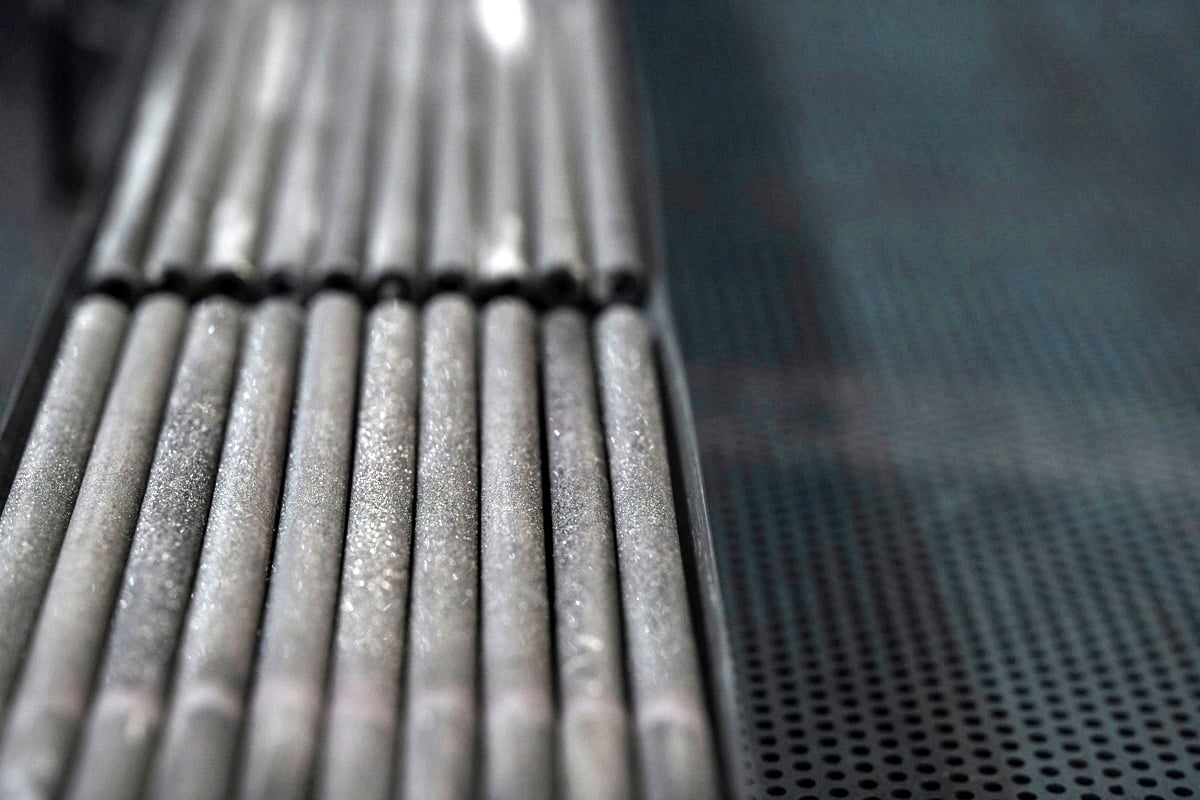

A key feature of the Globar® heating element is the unique microstructure of its substrate. This has been achieved through a thorough evaluation of the manufacturing process, starting from the initial preparation of the raw materials right through to the finished product.

“With the right raw materials, anyone can produce silicon carbide heating elements fairly easily, but they will not necessarily be very reliable or perform as cathode producers need them to,” McCabe says. “By analyzing the material structure and how it can be affected by process changes, we have been able to develop elements with the required reliability and uniformity needed for this application.”

For cathode material producers, this enhanced reliability means heating elements do not need to be changed as often, leading to lower maintenance time and costs, and the potential for the battery-maker end users to improve overall equipment effectiveness.

Globar® raw material

Globar® raw material

Highly protected

Another key benefit of the Globar® heating element’s highly engineered microstructure is lower porosity, which helps reduce the rate of reaction with the furnace atmosphere. In addition, Kanthal is looking at different ways to protect the elements in this type of application using engineered glazes/coatings.

“This is part of our continuous improvement work,” McCabe says. “Our aim is to protect the substrate from a number of different reactions including alkali and water vapor attack.”

Globar® structure

Globar® structure

“Globar® Glass Seal has been designed from the ground up over the last few years and is engineered specifically for Globar® and its unique microstructure,” McCabe says. “It will protect the substrate from a number of different reactions including alkali and water vapor attack and is particularly well suited for cathode material production.”

Higher yields, consistent quality

In addition to lower maintenance costs, the reliability of Globar® elements provides greater stability and temperature uniformity in the production process. This will help maintain productivity over time and ensure the same consistent quality in the end product.

“Elements react with the furnace atmosphere over time, and this can affect the uniformity of the hot zone, which is fairly critical in cathode production,” McCabe says. “Globar® elements have longer life and maintain temperature uniformity. For cathode producers, that can translate into increased productivity and improved process yields.”