Kanthal® APMT is an advanced powder metallurgical, dispersion strengthened, ferritic iron-chromium-aluminum alloy (FeCrAlMo alloy) recommended for continuous use up to 1250°C (2280°F) in oxidizing and reducing environments.

Kanthal® APMT has high creep strength and excellent form stability. Kanthal® APMT forms a protective and non-scaling Al2O3 surface oxide when exposed to high temperature, which gives good protection in most furnace and combustion environments, i.e. oxidizing, sulfidizing and carburizing, as well as against attacks from deposits of coke, ash, etc. The combination of excellent oxidation properties and form stability makes the alloy unique. The superior resistance of Kanthal® APMT to oxidation and carburization makes it very suitable for high temperature construction applications in various atmospheres.

Applications

- Radiant tubes for electrical and gas heated furnaces

- Retorts and muffles for heat treatment and high-temperature sintering of powder metallurgical components

- Shielding tubes

- Burner components, nozzles and flame detectors

- Load carriers, e.g. load carrying trays or baskets

- Furnace furniture, and furnace construction components

- Uncooled components in coal, gas, and biofuel fired power plants

- Thermocouple protection tubes in power plants and high temperature petrochemical processes

Values and diagrams are representative for all product forms in delivery condition unless otherwise stated. Values presented in imperial units are interpolated from tests made in SI-units.

Forms of supply

| Form | Dimensions (mm) | Dimensions (inch) | |

| Plate | Width | ≤ 1500 | ≤ 47.24 |

| Thickness | 3 - 20 | 0.12 - 0.79 | |

| Length | ≤3300 | ≤ 118.44 | |

| Extruded tubes | Outer dia. | 26 - 260 | 1.05 - 10.24 |

| Wall thick. | 2.87 - 11.0 | 0.11 - 0.43 | |

| Length** | 3000 - 13000 | 118.11 - 511.81 | |

| Cold Rolled Strip* | Width | ≤ 205 | ≤ 8.07 |

| Thickness | 0.2 - 3 | 0.01 - 0.12 | |

| Wire | Ø | 0.2 - 9.5 | 0.01 - 0.37 |

| Rod | Ø | 5.5 - 12 | 0.22 - 0.47 |

| Round bar | Ø | ≤ 100 | ≤ 3.94 |

| Length | ≤ 4500 | ≤ 177.17 | |

| Forging blanks | Width | ≤ 500 | ≤ 19.69 |

| Thickness | 35 - 170 | 1.38 - 6.69 | |

| Length** | ≤ 3000 | ≤ 118.11 | |

| Square bar | ф | ≤ 150 | ≤ 5.91 |

| Length | ≤ 4500 | ≤ 177.17 |

Other sizes and forms can be discussed on request

*) Cold rolled strip can be delivered as cut to length products

**) Length depending on cross section

Chemical composition

| C % | Si % | Mn % | Mo % | Cr % | Al % | Fe % | |

|---|---|---|---|---|---|---|---|

| Nominal composition | 3.0 | 21.0 | 5.0 | Balance | |||

| Min | - | - | - | 20.5 | - | ||

| Max | 0.08 | 0.7 | 0.4 | 23.5 | - |

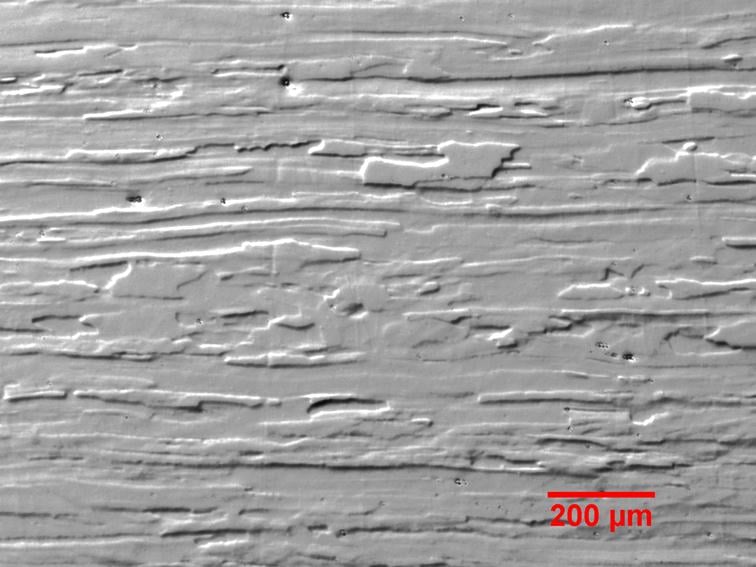

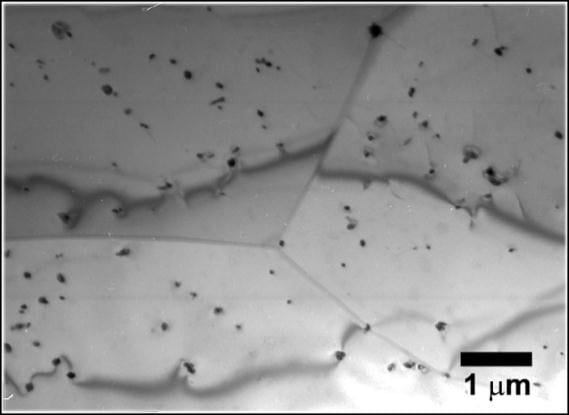

Microstructure

Structure is ferritic with typical average grain size 30-50 mm in delivery state. Grains are typically elongated in the long direction in wire and bar and are generally extended in the plane of flat products. Some product forms are subject to a secondary recrystallization after exposure to temperature exceeding 1000°C that typically leads to long and flat grains with length or width up to a few hundred µm.

|

|

|

| Polished and etched micrograph, from 8 mm hot rolled plate, delivery state | TEM section showing grain boundaries and particle dispersion |

Physical properties

| Density g/cm3 | 7.25 |

|---|---|

| Electrical resistivity at 20°C Ω mm2/m | 1.40 |

| Poisson's ratio | 0.30 |

| Temp. °C | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Ct |

1.00 | 1.00 | 1.01 | 1.01 | 1.01 | 1.02 | 1.02 | 1.02 | 1.03 | 1.03 | 1.03 | 1.03 | 1.04 |

Young's modulus

| Temperature [°C] [GPa] |

20 | 100 | 200 | 400 | 600 | 800 | 1000 |

| 220 | 210 | 205 | 190 | 170 | 150 | 130 |

Thermal conductivity

|

Temperature [°C] |

Thermal Conductivity |

Temperature [°F] |

Thermal Conductivity |

|

50 600 800 1000 1200 |

11 21 23 27 29 |

1200 1400 1600 1800 2000 2200 |

12.5 13 14 15.5 16 17 |

Coefficient of thermal expansion

|

Temperature [°C] |

Thermal Expansion (x10-6) [°C-1] |

Temperature [°F] |

Thermal Expansion (x10-6) [°F-1] |

|

20 - 250 20 - 500 20 - 750 20 - 1000 20 - 1250 |

12.4 13.1 13.6 14.7 15.4 |

68-400 68-600 68-800 68-1000 68-1200 68-1400 68-1600 68-1800 68-2000 68-2200 |

6.8 7.0 7.2 7.3 7.4 7.6 7.9 8.1 8.4 8.6 |

Specific heat capacity

|

Temperature [°C] |

Specific Heat Capacity |

Temperature [°F] |

Specific Heat Capacity |

|

20 200 400 600 800 1000 1200 |

480 560 640 710 670 690 700 |

68 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 |

0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.16 0.16 0.16 0.17 0.17 |

| Melting point | 1500°C (2732°F) |

|---|---|

| Magnetic properties | Ferromagnetic, Curie point approximately 600°C (1112°F) |

| Emissivity - fully oxidized material Ɛ | 0.70 |

Mechanical properties

Tensile properties at room temperature 20°C (68°F)

| Proof strength Rp0.2 MPa (ksi) |

Tensile strength Rm MPa (ksi) |

Elongation A % |

Hardness Hv |

|---|---|---|---|

| 510-600 (74-87) | 725-780 (105-113) | Typically 10-15 | 250 |

Note: Material in heavy sections generally has higher tensile strength and lower elongation values

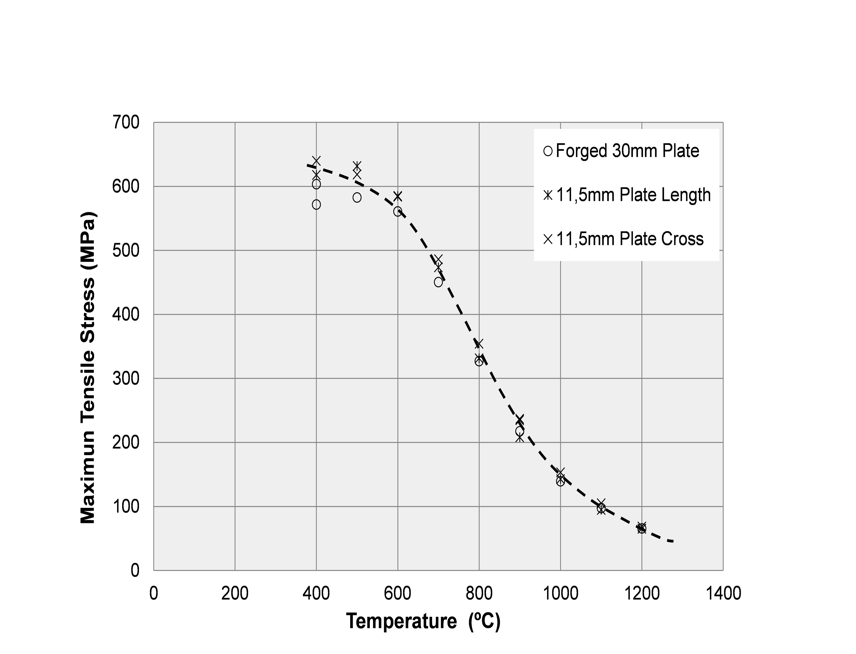

Mechanical properties at elevated temperature

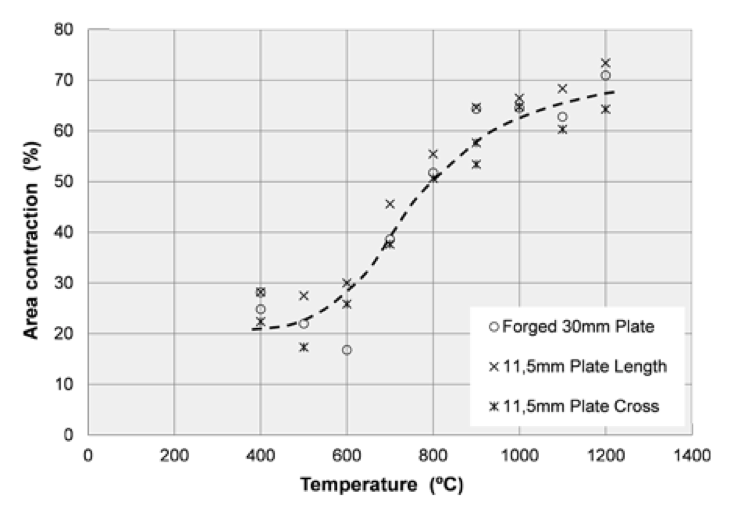

All values are representative average values in delivery condition. The samples are taken in the longitudinal direction from tube and in length and cross directions on hot rolled plate.

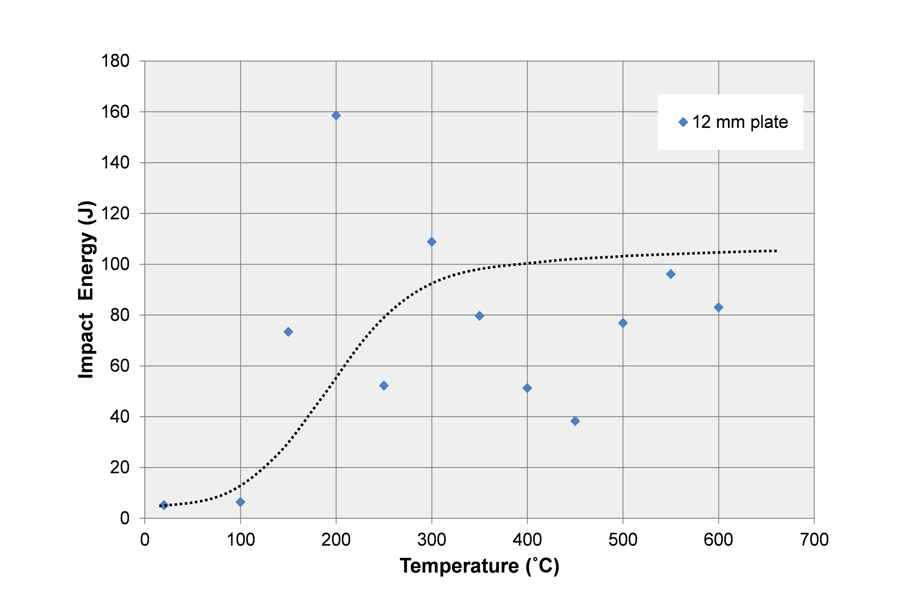

Impact test

The graph shows Charpy-V results tested on heating. Standard samples were machined from 12 mm hot rolled plate. A transition from low to high absorption energy regime occurs at around 200°C (390°F). Similar behavior exists for other product forms in relatively heavy section, like extruded tube.

|

Temperature °C (°F) |

Tensile strength Rm MPa (ksi) |

|---|---|

| 600 (1112) | 420 (61) |

| 800 (1472) | 120 (17) |

| 1000 (1832) | 42 (6) |

| 1200 (2192) |

16 (2.3) |

Hot tensile test - Gleeble test (deformation rate ~1 s-1)

| Time | Temperature/ Stress (MPa) | ||||||

|---|---|---|---|---|---|---|---|

| h | 700°C | 800°C | 900°C | 1000°C | 1100°C | 1200°C | 1300°C |

| 100 | 39.9 | 26.2 | 19.7 | 12.7 | 7.0 | 3.4 | 2.1 |

| 1000 | 36.8 | 23.4 | 16.2 | 9.9 | 5.0 | 2.3 | 1.5 |

| 10000 | 34.0 | 21.0 | 13.2 | 7.8 | 3.6 | 1.6 | 1.2 |

| 100000 | 31.4 | 18.8 | 10.8 | 6.1 | 2.6 | 1.1 | 0.9 |

1% elongation data are calculated from minimum strain rate data. In general, there is an initial amount of primary creep in the order of 0.3 - 1% depending on product form, temperature and stress level. Total elongation to rupture depends on temperature and stress but is typically in the order of 3 to 12% where the lower range is representative for low stress levels.

| Time | Temperature/ Stress (MPa) | ||||||

|---|---|---|---|---|---|---|---|

| h | 700°C | 800°C | 900°C | 1000°C | 1100°C | 1200°C | 1300°C |

| 100 | 45.0 | 29.2 | 21.6 | 14.4 | 8.7 | 4.6 | 2.7 |

| 1000 | 39.7 | 24.8 | 17.0 | 10.8 | 5.5 | 2.5 | 1.5 |

| 10000 | 35.0 | 21.1 | 13.4 | 8.1 | 3.5 | 1.4 | 0.9 |

| 100000 | 30.8 | 18.0 | 10.6 | 6.1 | 2.3 | 0.8 | 0.5 |

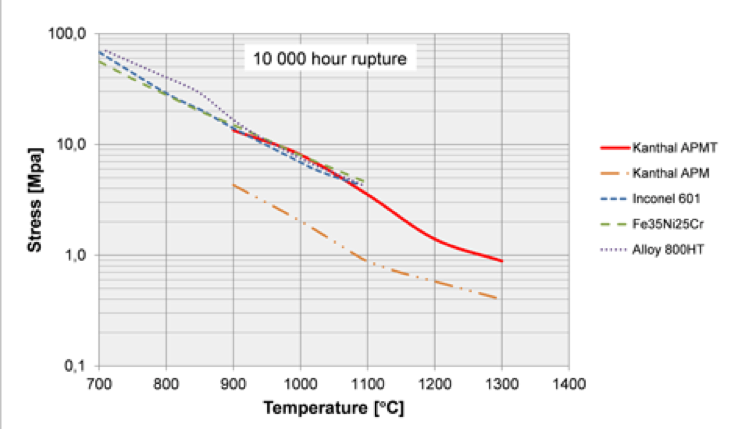

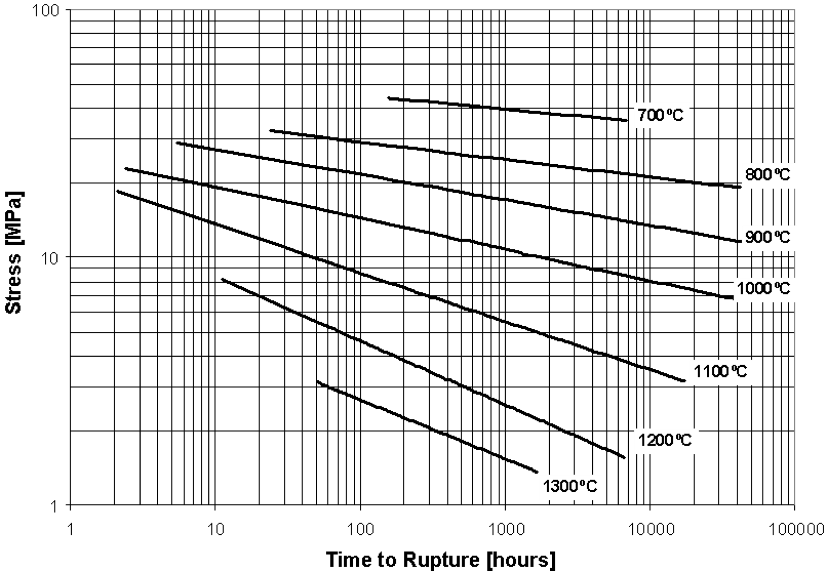

Creep rupture data are representative average values for tube, bar and hot rolled plate based on creep tests performed within the time and temperature range indicated by the length of the solid lines in the diagrams (test times less than 50 000 hours). It should be pointed out, that component lifetime on thinner sections may be limited by oxidation/corrosion rather than creep rupture at low stress levels and long exposure times as indicated by the shaded area in the tables. 10 000 hour rupture compared to some other alloys are given in diagram.

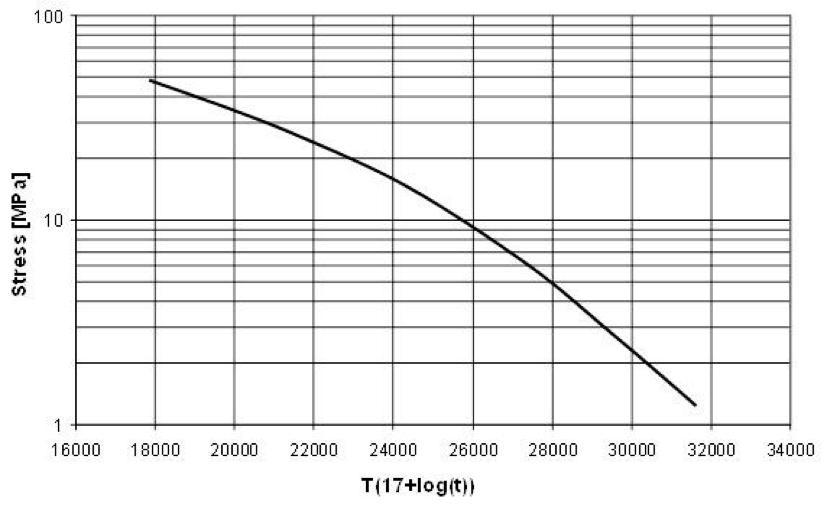

Creep rupture stress

Larsson-Miller diagram

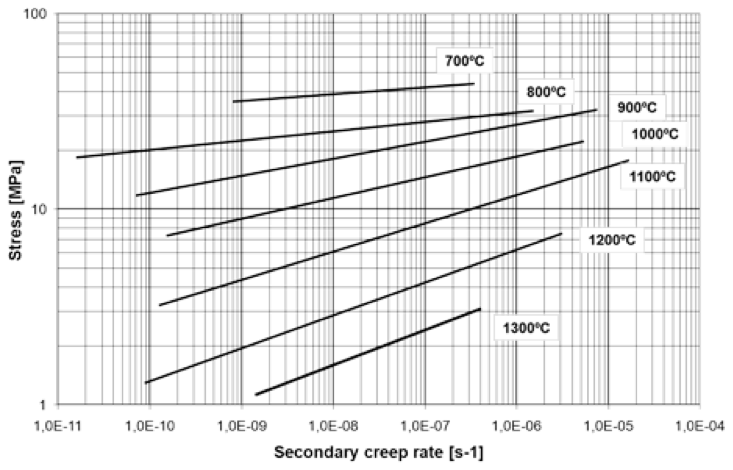

Secondary creep rate

Corrosion resistance

High Temperature Oxidation and Corrosion Properties

Kanthal® APMT exhibits excellent high temperature corrosion properties due to the spontaneous formation of a thin layer of aluminum oxide (Al2O3) that protects the base material from corrosion attack. The most important properties of the scale are summarized below:

- Thermodynamically stable – forms also in protective atmospheres at very low dew points

- Inert – once formed, it is very stable with respect to chemical reactions

- Dense – forms a very effective barrier against carbon diffusion and penetration from contaminants

- Thin – very small amounts of aluminum is consumed to form and maintain the scale which results in very long oxidation life time

- Adherent – resistant to spallation during thermal cycling

Oxidation Properties

The oxidation resistance of Kanthal® APMT is superior to that of Ni-base and high alloyed austenitic chromia forming alloys due to its alumina protection. It gives less scale spallation, and alumina is, in contrast to chromia, not sensitive to emit volatiles in humid atmospheres.

Kanthal® APMT is recommended for service in air and in most oxidizing and reducing gases up to 1250°C (2280°F) which is approximately 100°C (180°F) higher than that of the best performing chromia forming alloys. For shorter periods, temperature up to 1300°C (2372°F) is acceptable without substantial detrimental effects.

Corrosion resistance in dry N2 or H2/N2 is very good when DP is higher than -25°C (-13°F). Below this level of water content, the alloy might be susceptible to nitriding in certain situations.

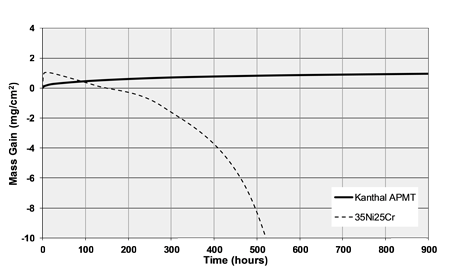

The figure below shows mass change during intermittent oxidation in air at 1100°C. After an initial period, cycle times were approximately 100 hours. Kanthal® APMT shows a sub-parabolic weight gain, while the oxide scale on the Fe25Cr35Ni alloy starts to flake after less than 24 hours.

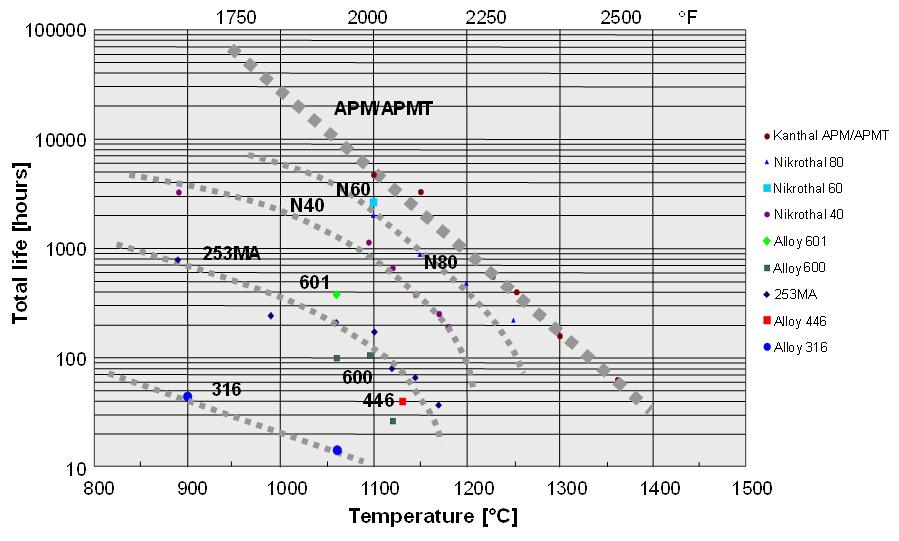

Oxidation limited lifetime

Oxidation limited lifetime is determined by the gradual consumption of Al within the alloy. The protective alumina scale breaks down after extended time at high temperature when the level of Al has reached between 1 and 3 wt% depending on temperature and thermal cycling. Comparative oxidation lifetime may be estimated according to ASTM B78-81. The test is performed on Ø 0.7 mm wire and results are shown in the diagram for Kanthal® APMT and some other high temperature alloys.

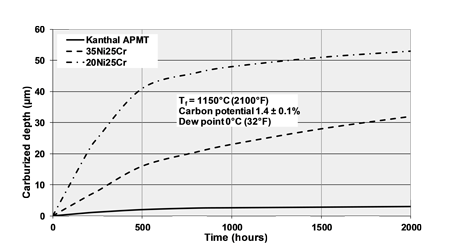

Carburization Properties

The formation of a protective alumina scale gives Kanthal® APMT superior resistance to carburization compared to chromia forming alloys.

In the figure below the average depth of carburization was calculated based on total loss of material during the test.

Heat Treatment

Pre-oxidation

Pre-oxidation treatment results in a protective alumina scale of around 1 µm thickness that is ideal for further exposure in corrosive environments. Prior to heating, the surfaces should be cleaned from any dirt, debris, oils, etc. which may otherwise have a negative effect on the protective oxide. Recommended pre-oxidation parameters are 8 hours at 1050°C. Cooling rate: 50°C/h down to 500°C followed by cooling in air. Use of e.g. fans or pressurized air to create forced cooling is not recommended.

Stress relieve

Stress relieve can be made after further forming processing, and is necessary after welding. Recommended parameters are 1 hour at 850° in air, in addition to the time needed for the heat to soak through the entire thickness of the material. Cooling rate: 100°C/h down to 500°C followed by cooling in air. Use of e.g. fans or pressurized air to create forced cooling is not recommended.

Fabrication

Kanthal® APMT can be formed at room temperature, but since the room temperature impact strength is comparatively low, it is nevertheless recommended that plastic deformation is performed using a preheating to T≥250°C (480°F).

Bending over edge with radius give less localized stress compared to V-bending and is preferred. For plates and strip the edge bending radius Rmin ≥ 3t is recommended, however Rmin ≥ 2t is generally possible for plates of t ≤ 5 mm.

For tubes, inductive bending with heating to 875°C is recommended. Normally no stress relieving heat treatment is necessary after the bending process. Minimum radius of bending, with acceptable change of wall thickness ± 10 %, can be calculated from

Rmin = 3 O.D.

Where O.D. is the outer diameter of tube and radius of bending is defined from the centerline of the tube.

Cutting and Machining

Water jet is the recommended way of cutting Kanthal APMT. Low speed saw cutting with abundant cooling can also be used.

The machinability of Kanthal® APMT is comparable to that of forged or rolled ferritic stainless steels. The cutting speed however, normally needs to be reduced compared to standard grades. A starting point for optimization to approximately half is recommended in order to control the tool temperature. For most machining operations, standard emulsion based coolants can be used. An exception is gun drilling operations, in which case neat oil gives less tool wear.

Joining

Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when the actual service conditions are known. Continuous development may necessitate changes in welding technical data without notice.

The most commonly used method for joining APMT is conventional TIG/GTAW-welding. Alternative joining methods like riveting and threading has been tested and may be useful for certain applications and has the advantage that the strengthening particle dispersion remains intact.

Welding

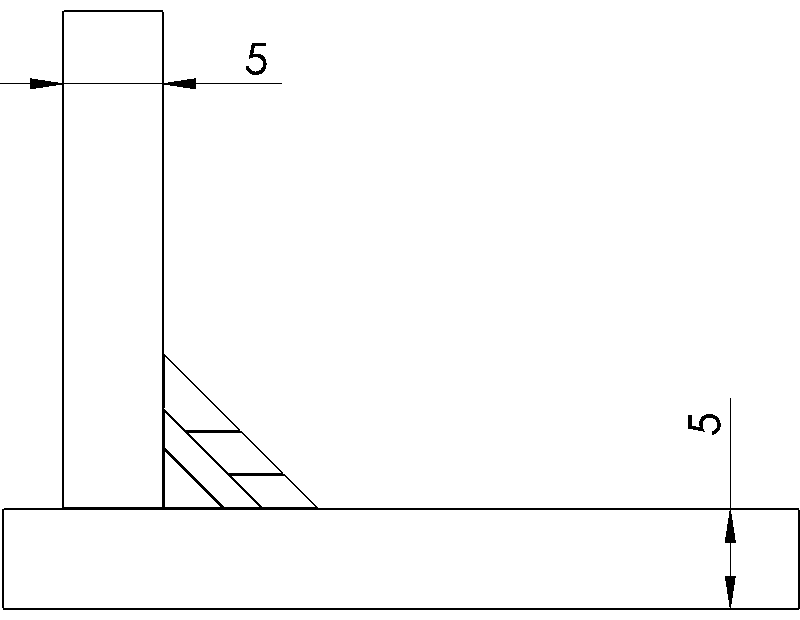

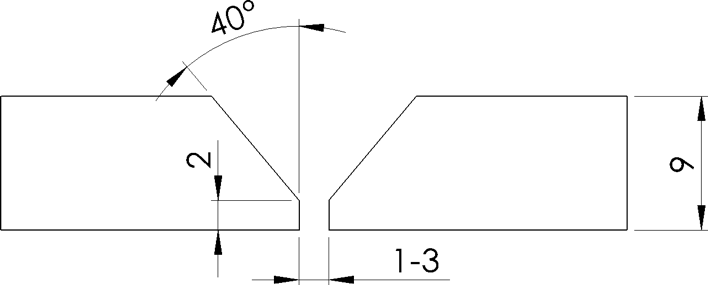

Examples of weld preparations and TIG/GTAW settings that has resulted in successful V-groove butt welds and fillet welds are show below. For welding thin plates of Kanthal APMT, a lower current is more suitable. These welds were made with pre-heating to 250 ± 50 °C (480 ±90°F), and kept warm until the joint was stress relieved at 850 °C for 1 hour. Pure argon is recommended as shielding gas. It is highly important that the gas does not contain additions of CO2 or NO.

|

Pass |

Current [A] |

Voltage [V] |

Polarity |

Travel speed [mm/min] |

Shielding gas |

|

Root |

75-95 |

12-14 |

DCEN |

15-30 |

Ar 99.99% |

|

2-3 |

150-175 |

13-16 |

DCEN |

40-70 |

Ar 99.99% |

|

4+ |

150-175 |

13-16 |

DCEN |

75-110 |

Ar 99.99% |

|

Pass |

Current [A] |

Voltage [V] |

Polarity |

Travel speed [mm/min] |

Shielding gas |

|

1 |

160-180 |

13-16 |

DCEN |

70-100 |

Ar 99.99% |

|

2+ |

160-180 |

13-16 |

DCEN |

70-100 |

Ar 99.99% |

Welding consumables

For TIG/GTAW welding, wire Ø1.6 or 2.4mm may be used. Ø1.6 mm is recommended for the root pass and for subsequent passes 1.6 or 2.4 mm can be used.

When welding APMT to other materials, APMT is usually the more sensitive of the two materials and the welding can be carried out as when welding APMT to APMT.

Recommended welding consumables for APMT towards some common alloys

| Weld towards | Filler |

| Kanthal APMT | Kanthal APMT |

| Ni-base alloys, 600, 601 | Kanthal APMT or Exaton Ni72HP |

| High alloy austenitic stainless steel, 310, 353MA, 253MA, 800, HK40, HP | Exaton 25.20L |

| Austenitic stainless steel, 304, 316, 347 |

Exaton 25.20L |

| Ferritic stainless steels, 409, 430, 446 | Kanthal APMT |

| Carbon and low alloy steel | OK Autrod 12.64 |

Preheating

Preheat to 250 ± 50 °C (480 ±90°F) is recommended. If possible, preheating with open flame/torch should be avoided, or if the only option, be performed by personnel experienced in welding APMT due to the difficulties of attaining an even temperature distribution on the weld area.

If necessary, reheating of the weld area should be performed in order to maintain the temperature of the weld at minimum 200°C (390°F) during the welding procedure.

Post weld heat treatment - PWHT

A post weld stress relieve has to be carried out directly after welding. The weld is not allowed to cool below 200°C (390°F) before the post weld heat treatment is performed. For parameters, see heat treatment. We recommend a combined stress relieve and pre-oxidization of the weld area in conjunction with the post weld heat treatment in case of APMT to APMT welding.

Initial cleaning and post weld cleaning

Degreasing of the joint faces should be done prior to welding. Post weld cleaning can be done mechanically by stainless steel brush.

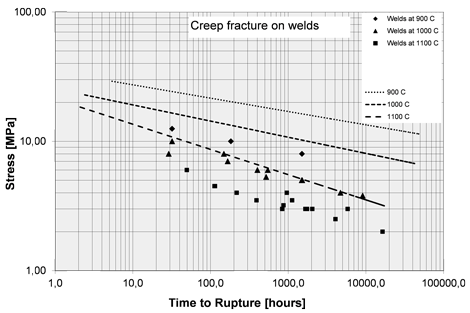

Retained strength in the weld

Kanthal® APMT is an advanced powder metallurgical dispersion strengthened alloy and welding will have a negative impact on the mechanical and high temperature creep properties of the material. The reason is the disruption of the grain structure and the distribution of the dispersion. Representative data from creep strength of TIG welds made with Kanthal® APMT filler can be seen in the diagram. For example, at 1000°C (1830°F), the weld rupture strength can be compared to unaffected material at 1100°C (2010°F).

Additional information

These guidelines/recommendations take oxidation and corrosion properties during prolonged exposure to high temperature into consideration. Therefore our recommendations may differ from traditional welding recommendations used in construction welding. For further advice, contact your local Sandvik Heating Technology sales representative.