THE CHALLENGE

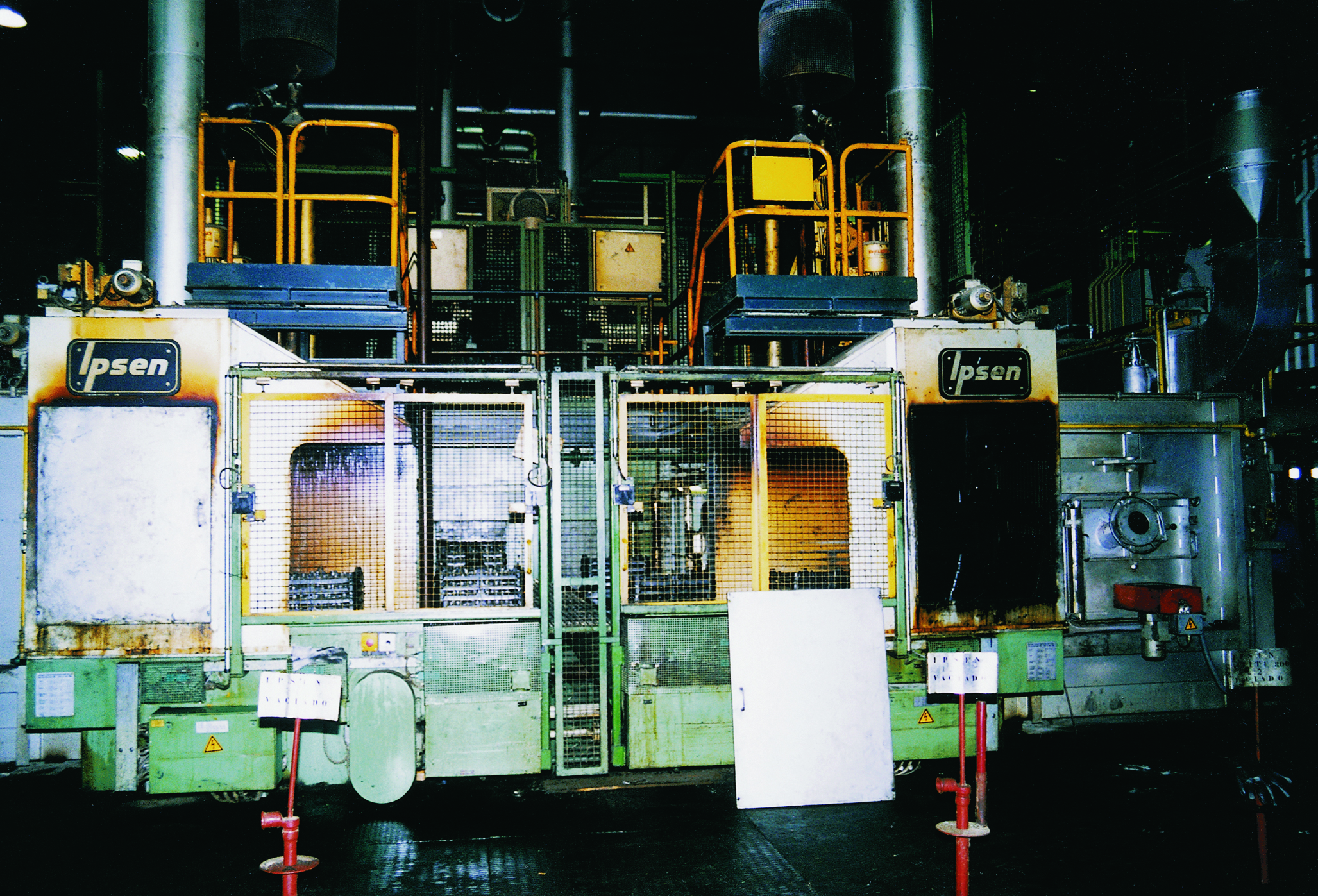

The heat treatment is carried out in four continuous gas fired pusher furnaces and in a two sealed quench furnaces.

Production reliability is of course critical, and the furnaces must operate at tight production schedules where production stoppages would cause severe problems.

One of the four gas heated continuous furnaces at Gearbox. Kanthal® APM tubes are installed as inner and outer tubes.

One of the four gas heated continuous furnaces at Gearbox. Kanthal® APM tubes are installed as inner and outer tubes.

THE SOLUTION

Kanthal® APM inner and outer tubes in the recuperative systems were installed on trial and they have outperformed the different previous systems by far. The lifetime is superior and the rating is higher.

The four continuous furnaces are running at 880–930°C (1620–1710°F) with endogas atmosphere, heated by natural gas. Originally, they were equipped with silicon impregnated silicon carbide inner tubes and nickel-chromium outer tubes.

The encouraging experiences with Kanthal® APM metallic tubes in other similar furnaces made Gearbox install them on trial in one furnace. Compared to the original system’s tubes Kanthal® APM had a longer lifetime and no tubes had to be exchanged during the production periods. Step by step the tubes are now changed to Kanthal® APM.

Ipsen T4 with Kanthal® APM tubes forrapid cooling

Gearbox is also operating two Ipsen T4 gas heated furnaces for smaller batches and as a complement to the large continuous furnaces. They are running at maximum 950°C (1740°F) and have eight tubes each. The total power is 144 kW.

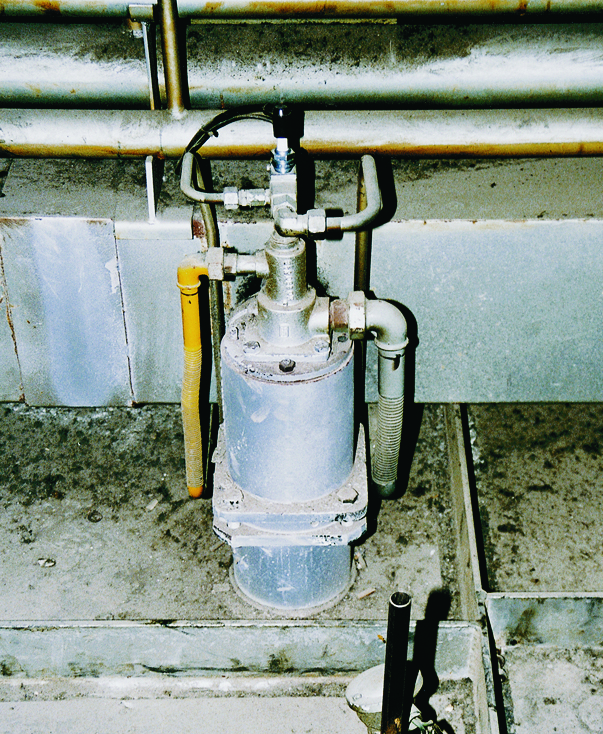

The recuperative system with Kanthal® APM tubes. The inner tube is (outer diam. x wall thickness x L) 87 x 5 x 875 mm (3.4 x 0.2 x 34.4 in) and is loaded at 6.3 W/cm2 (1.0 W/in2). The outer tube is 128 x 5.5 x 1650 mm (5 x 0.2 x 65 in) and is loaded at 4.2 W/cm2 (0.7 W/in2). The system is rated at 20.5 kW and there are 30 units in each furnace.

The recuperative system with Kanthal® APM tubes. The inner tube is (outer diam. x wall thickness x L) 87 x 5 x 875 mm (3.4 x 0.2 x 34.4 in) and is loaded at 6.3 W/cm2 (1.0 W/in2). The outer tube is 128 x 5.5 x 1650 mm (5 x 0.2 x 65 in) and is loaded at 4.2 W/cm2 (0.7 W/in2). The system is rated at 20.5 kW and there are 30 units in each furnace.

THE RESULT

Kanthal® APM tubes were installed and the lifetime is superior to the previous ceramic tubes. The tubes are also equipped with flame busters made from Kanthal® APM, twisted strips that improves the efficiency by creating turbulence around the gas flame.