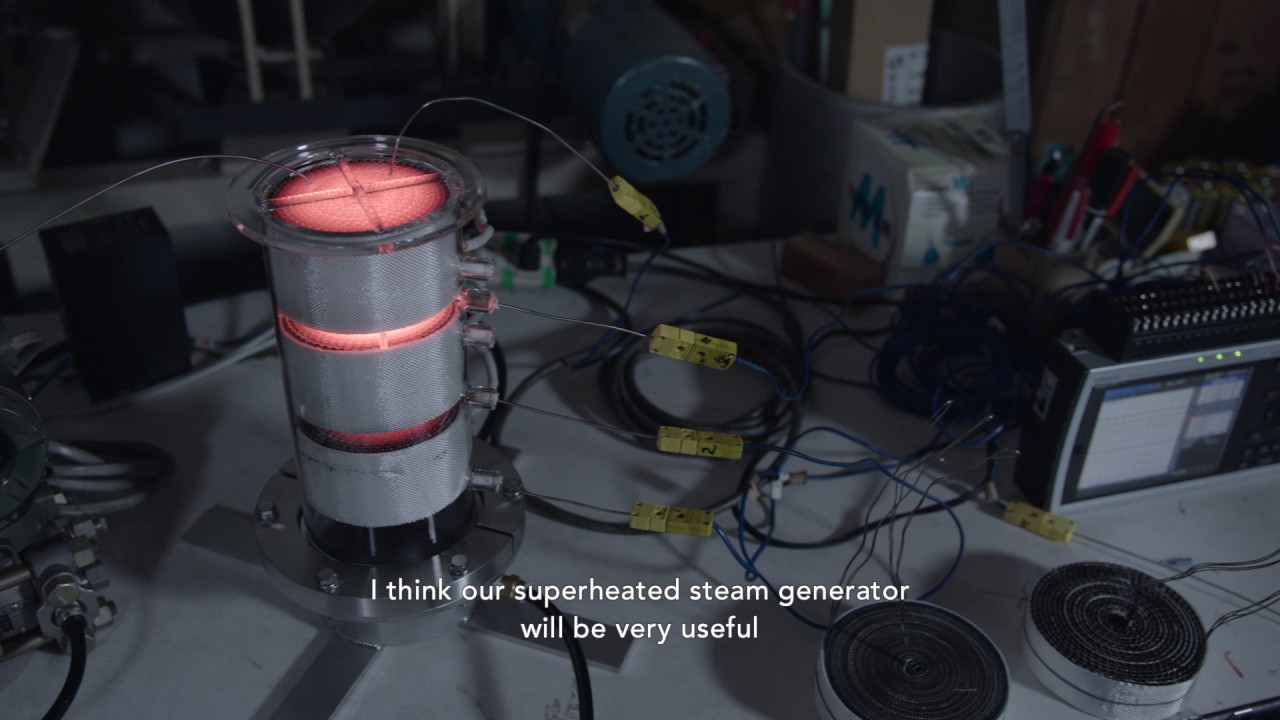

Shinsuke Ohara, president and founder of Oparz, has developed a sterilization equipment to kill microorganisms through a heating process.

Shinsuke Ohara, president and founder of Oparz, has developed a sterilization equipment to kill microorganisms through a heating process.

As the novel coronavirus spreads across the world, governments and companies are taking unprecedented steps to halt the advance of the virus. The Japanese company Oparz wants to join the fight by deploying Perfect Clean, a device with one-pass sterilization capability, composed of a metal filter, a blower and an air-cooled heat exchanger.

The unique part of the Perfect Clean solution is the metal filter, called the 3D Heater. Made from Kanthal® AF alloy, it uses heat of at least 350 degrees Celsius to kill all bacteria or viruses that pass through – an important safety measure in hospital environments.

“Our ancestors killed microorganisms by heating to prevent the spread of infection when ancient epidemics occurred,” says Shinsuke Ohara, president and founder of Oparz. “We used this knowledge when developing this sterilization equipment to kill microorganisms through a heating process.”

Used in a closed space such as a hospital room, the 3D Heater provides non-infectious air to the medical staff.

“Commonly, HEPA filters are used for such purposes, but they need to be replaced regularly and cannot be disposed as general waste, since the filters still contain small amounts of active virus and consequently need to be handled carefully,” Ohara says. “The 3D Heater, on the other hand, burns the virus completely. Moreover, it can be used 24/7, year-round, without maintenance, which means there are no extra costs for replacement filters.”

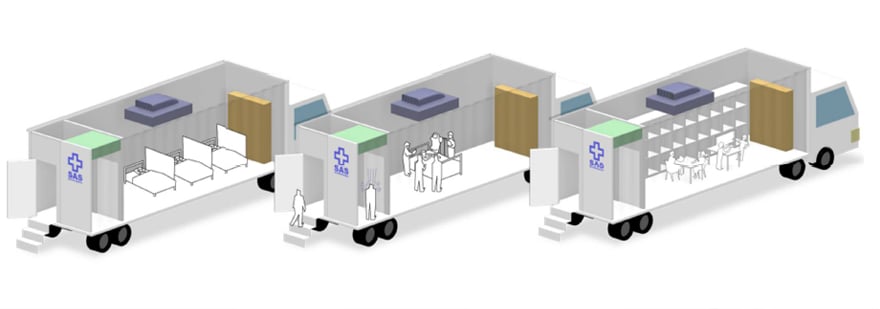

The 3D Heater is the key technology in the Safe Air System concept. Trailers are used as sterilized rooms and can be moved anywhere at any time to meet emergency needs.

The 3D Heater is the key technology in the Safe Air System concept. Trailers are used as sterilized rooms and can be moved anywhere at any time to meet emergency needs.

Mobile solution for emergency situations

The 3D Heater has been around since 2003 and is in use at tuberculosis hospitals in Japan. In 2013, Oparz introduced the Safe Air System concept, which uses the 3D Heater as the key technology to prevent secondary infections in healthcare workers and hospitals during virus outbreaks, such as recurring influenza viruses or the current coronavirus.

The concept includes various mobile hospital solutions, using trailers as sterilized rooms equipped with a Safe Air System that can be moved anywhere at any time to meet emergency needs.

The 3D Heater is heated to 350 degrees Celsius or more, which is high enough to burn any bacteria or virus into ashes.

The 3D Heater is heated to 350 degrees Celsius or more, which is high enough to burn any bacteria or virus into ashes.

Could help ease pandemic

The Safe Air System concept has been presented to both the European Biosafety Association and the Japanese Biological Safety Association, but it has not yet been put to use to combat Covid-19.

“There might be some concern about the effectiveness of Perfect Clean against Covid-19,” Ohara says. “We haven’t been able to collect any data to prove its effectiveness, since this is the first-ever outbreak of Covid-19 in the world. However, we strongly believe that our solution could help to ease the pandemic situation, as filtered clean air is important in the hospital environment.”

Oparz was a finalist for the 2016 Kanthal® Award. Watch our video here:

The 3D Heater technology

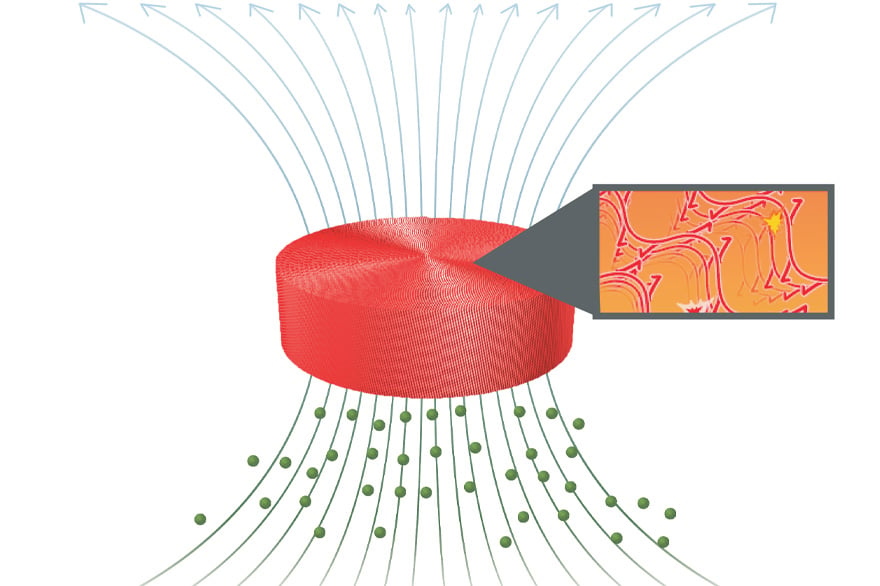

At the core of the 3D Heater is a porous aggregate called Palblat. It is a metallic foil between 15 and 50 micrometers thick, processed with microscopic through-holes evenly throughout the foil and with burrs on both sides.

To form the 3D Heater, electrodes are attached before the Palblat is rolled into a coil and bound together using aluminum oxide tape.

Related information

Read more about the Kanthal® AF alloy in our Product section.