Leading by example

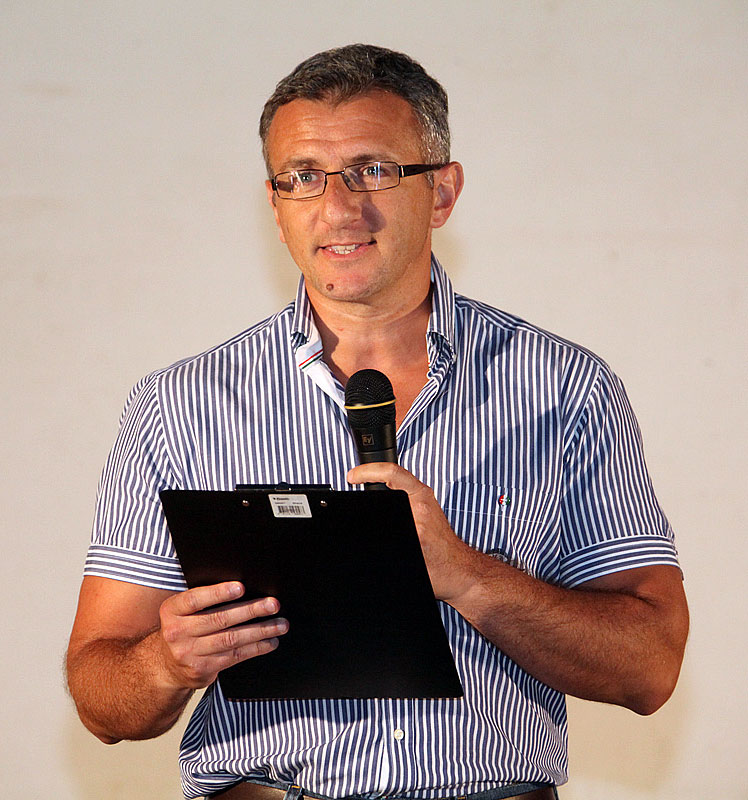

Giuseppe Randazzo, General Manager PU Bethel, Kanthal"Reduced CO2 emissions, heightened energy efficiency, and an improved work environment show that we walk the talk in terms of sustainability. And it does not hurt as the investment not only aligns seamlessly with our sustainability targets but also promises significant returns on investment," declares General Manager, Giuseppe Randazzo.

Giuseppe Randazzo, General Manager PU Bethel, Kanthal"Reduced CO2 emissions, heightened energy efficiency, and an improved work environment show that we walk the talk in terms of sustainability. And it does not hurt as the investment not only aligns seamlessly with our sustainability targets but also promises significant returns on investment," declares General Manager, Giuseppe Randazzo.

"Our inaugural step? The installation of state-of-the-art lighting solutions within our facility, which commenced at the end of January," Randazzo shares with enthusiasm.

Kanthal is committed to making significant upgrades and changes to improve energy consumption patterns. Part of this involves replacing outdated transformers with high-efficiency alternatives. These changes will have a significant impact on energy consumption and represent a major shift in the company's approach.

"We're tackling inefficiencies head-on, identifying and rectifying air leaks while pioneering an ingenious heat recovery system that harnesses excess heat generated during production to power our operations sustainably," explains Maintenance Manager Steven Valletta.

Numbers and beyond

Investments like these are a great example of how energy and cost efficiency go hand in hand with other environmental and work environment benefits.

Steven Valletta, Maintenance Manager, KanthalThe aforementioned initiatives are projected to yield annual energy savings equivalent to approximately 300 tons of CO2 emissions from the site underscoring the viability of eco-conscious practices in today's business landscape.

Steven Valletta, Maintenance Manager, KanthalThe aforementioned initiatives are projected to yield annual energy savings equivalent to approximately 300 tons of CO2 emissions from the site underscoring the viability of eco-conscious practices in today's business landscape.

"Our vision extends beyond mere bottom-line gains," Randazzo asserts. "We recognize the intrinsic value of fostering a conducive work environment, one characterized by reduced noise levels and ergonomic enhancements. These improvements not only boost employee well-being but also serve as a powerful testament to our commitment to responsible business practices."

“Investments like these are a great example of how energy and cost efficiency go hand in hand with other environmental and work environment benefits,” says Nicolai Schaaf, Kanthal Sustainability Manager. “Scaling up these efforts is important also for our products in electric industrial heating. While we need more renewable electricity to fuel the grids, we need to maximize efficiency on all ends to manage the demand.”

Green funding

The project to improve Bethel's energy conservation program is being partly financed through green funding from the local electricity provider. Due to the high demand for electricity in the US, many providers offer incentives for conservation programs in homes and businesses. After an audit by a certified subcontractor identified the main areas for improvement in Bethel, the electricity provider agreed to subsidize 65% of the project cost. The project is expected to be completed by mid-2024 once all necessary steps have been taken.

In Bethel, the winds of change are blowing, and Kanthal is proud to be at the forefront of this historic transformation.