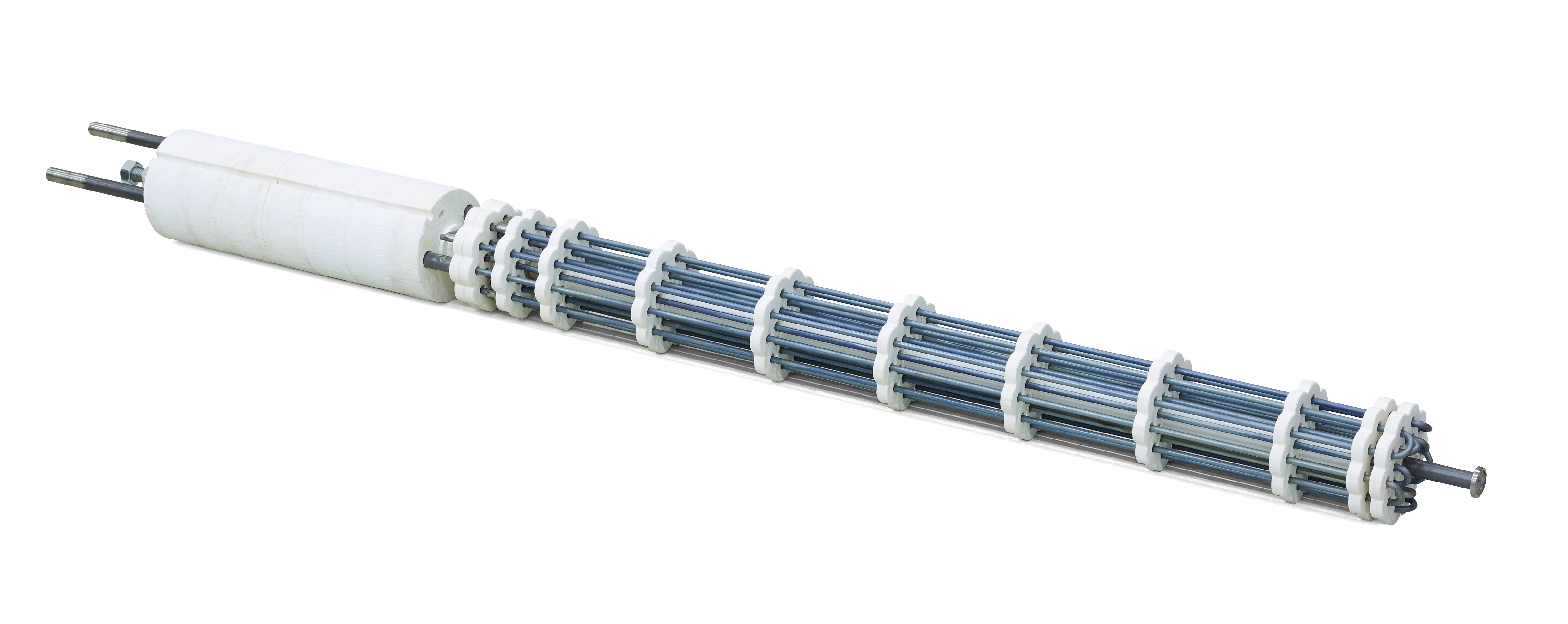

Tubothal® electric heating elements are made of heavy Kanthal® APM wire rod and rated at 5.5 – 7.8 kW each, loaded at 2.88 – 3.9 W/cm2 (0.45 – 0.6 W/in2). The Kanthal® APM tubes are 1380 mm (54.3 in) long, outside diam. 83 mm (3.3 in), loaded at 2.5 – 3.4 W/cm2 (0.39 – 0.53 W/in2).

Tubothal® electric heating elements are made of heavy Kanthal® APM wire rod and rated at 5.5 – 7.8 kW each, loaded at 2.88 – 3.9 W/cm2 (0.45 – 0.6 W/in2). The Kanthal® APM tubes are 1380 mm (54.3 in) long, outside diam. 83 mm (3.3 in), loaded at 2.5 – 3.4 W/cm2 (0.39 – 0.53 W/in2).

THE CHALLENGE

Tubothal® and Kanthal® APM tubes for 1050°C (1920°F)

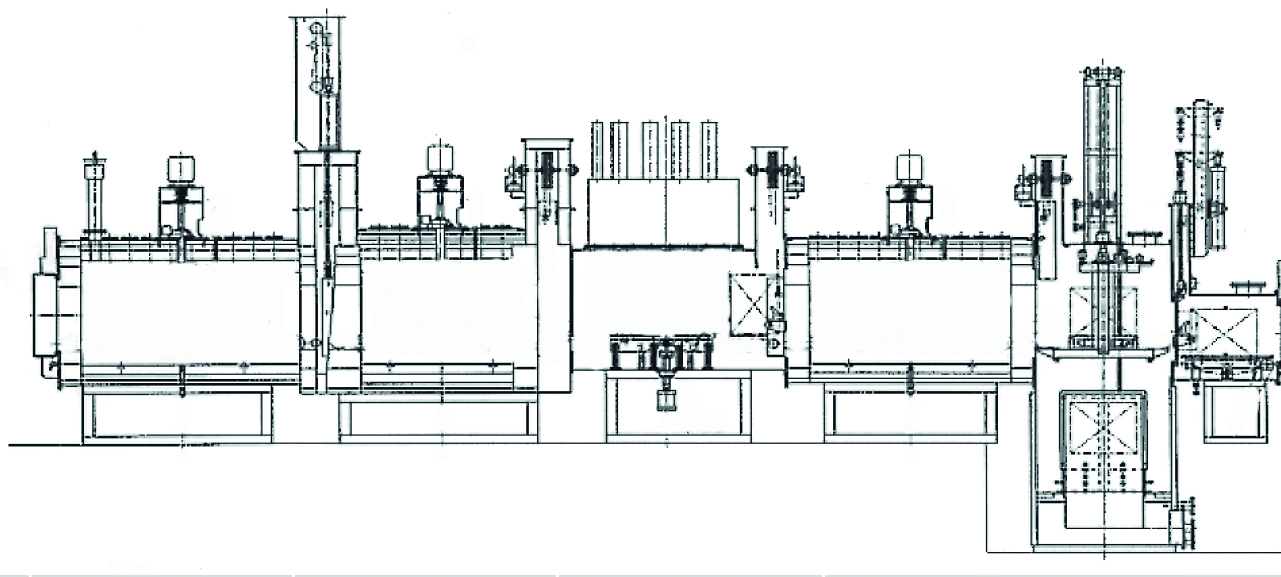

Dowa Mining Thermotech Division is a commercial heat treater and furnace builder in Japan. One of their customer was running a continuous carburizing furnace at 930°C (1700°F) for auto parts but needed higher capacity. Different alternatives were discussed with Dowa and in contacts with Kanthal, it was discussed if Kanthal could supply a system for the planned high temperature of 1050°C (1920°F). Tubothal® system seemed to be the answer to the problem.

THE SOLUTION

The Tubothal® system comprises a high power, multi-shank, heavy gauge Kanthal® APM wire heater combined with a Kanthal® APM radiant protection tube. A primary advantage of Tubothal® tube system is the formation of a cohesive aluminum oxide film on both the inner and outer surface of the radiant tube and on the heater material itself, thus Tubothal® elements remain free from contamination by internal scaling of the tube. The adherent alumina film formed on the outside of the tube is an extremely effective barrier against carbon activity and makes the tubes highly resistant to carburization even in cases where free carbon is al lowed to accumulate on the tubes. Another specific advantage of the system is its ability to work at elevated temperatures – up to 1250°C (2280°F) furnace temperature

is possible, which is unique for a metallic system. Tubothal® system is in fact the only metallic system that could work at the planned 1050°C (1920°F).

High loading

Compared to nickel-chromium elements and tubes, Tubothal® elements and Kanthal® APM tubes can be much higher loaded without running the risk of shortening the operating life. The total furnace power can be increased, in this case by 30 %, and consequently the production capacity is much improved.

The decision was made to convert the furnace to Tubothal® and Kanthal® APM tubes.

The design work was completed, and the old nickel-chromium heaters and tubes were removed and replaced by Tubothal® and Kanthal® APM tubes.

This first 407.1 kW rated high temperature continuous carburizing furnace is equipped with a total of 69 Ø 68 mm (2.7 in) Tubothal® heaters fitted inside Ø 83 mm (3.3 in) O/D Kanthal® APM radiant protection tubes. The power per element is varying between 5.5 and 7.8 kW. The furnace atmosphere is endothermic with a carbon potential at the carburizing zone of 15%.

THE RESULT

Tubothal® maintenance free system – no elements or tubes replaced

After 18 month of operation, the results of the new system are quite satisfactory. So far, the Tubothal® system has been totally maintenance free.

None of the tubes or heaters has been replaced and no carburization of the tubes has been noticed. The carbon deposits on the tubes, if any, can easily be brushed off. The increased total power and the higher temperature have resulted in a 30% higher production capacity. Based on these experiences, Dowa is planning to install high temperature processes with Tubothal® system in a number of other furnaces.