Another important advantage of Kanthal Super HT elements is the greater hot strength and form stability at high temperatures, also enabling predictable and higher productivity.

Kanthal Super HT heating element achieves high purity – the golden standard in dentistry – and reduces the greenish or yellowish tones often generated by impurities in other types of heating elements. Kanthal Super HT contributes to an end product with a clean, white look (pictured left).

Kanthal Super HT heating element achieves high purity – the golden standard in dentistry – and reduces the greenish or yellowish tones often generated by impurities in other types of heating elements. Kanthal Super HT contributes to an end product with a clean, white look (pictured left).

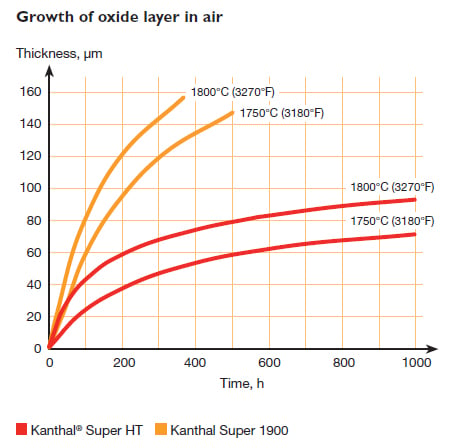

Reduced growth of oxide layer

In temperatures of up to 1830°C (3330°F), Kanthal Super HT allows for a faster heating and cooling process that sharply reduces the growth in the oxide layer compared to other heating elements available on the market. Consequently, oxide layers are kept to a minimum, reducing the tension between the base material and the surrounding oxide. By minimizing the risks for breaking or cracking, furnace productivity is increased and element life is extended.

Kanthal Super HT advantages

- Rapid cycling

- High surface load

- Lower oxidation rate

- Thinner glaze layer

- Longer life at high temperatures

- Improved hot strength

Standard product range

Kanthal Super HT heating element is delivered as two- and four-shank elements with fixed terminals as standard for safe and reliable electrical connections. Special designs are available on request.

| Heating zone diam. Le | Terminal diam. Lu | ||

|---|---|---|---|

| mm | in. | mm | in. |

| 2.5 | 0.10 | 6 | 0.24 |

| 3 | 0.12 | 6 | 0.24 |

| 4 | 0.16 | 9 | 0.35 |