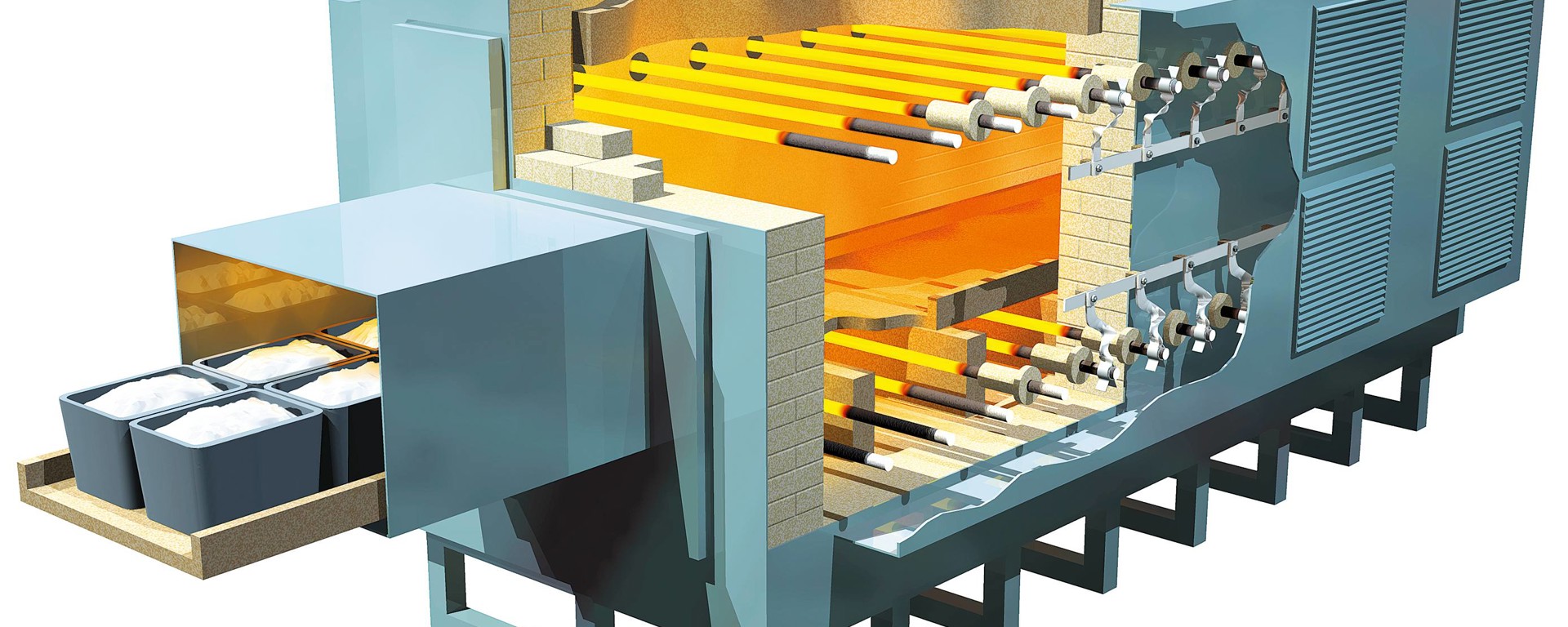

Carburization of steel products creates a harder outer surface through the application of heat which diffuses the carbon in the material. This creates a thinner stronger outer layer, also known as case hardening.

The Kanthal® offering for carbuization allows for precise control of temperature with electrical heating elements. The harsh atmospheres of the furnaces often lead to shorter lifetimes of heating elements and requiring more downtime to fix.

However, the introduction of Kanthal® APM is the choice of many in the industry for longer life at temperatures up to 1050°C (1920°F).

Take a look at our customers' success, other industries or products for continuous furnaces.

Connected products

Here you can find the Kanthal product offering