Content:

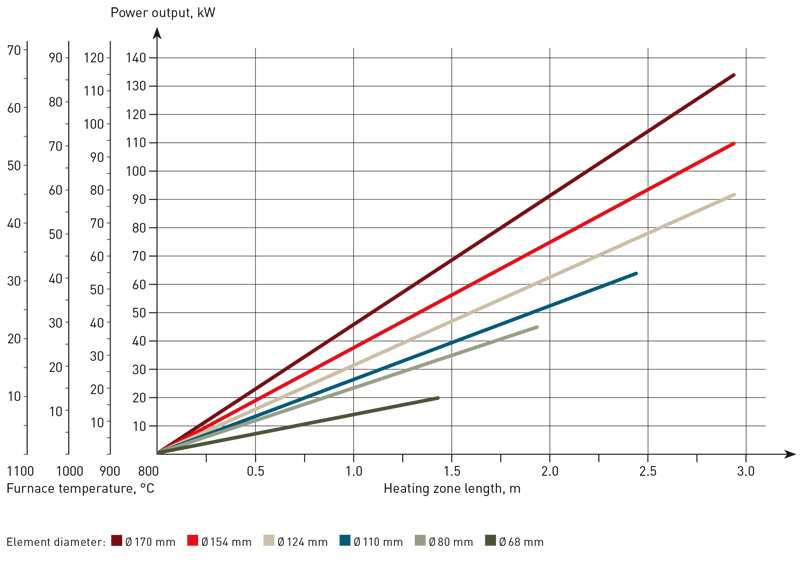

Maximum design power outputs for all standard element diameters at different furnace temperatures

Higher power output

Power supply

Tubothal® benefits

The variety of applications where the Tubothal® system can be used is vast. The main areas of use are in heat treatment, aluminum and steel industry furnaces. The high loading capabilities of both Tubothal® elements and Kanthal® APM tubes can be exploited to the full in new furnaces and conversions from traditional radiant tube designs. In both cases, higher power and/or higher temperatures can be obtained, or a similar output can be achieved with fewer assemblies installed, leading to improved furnace flexibility and lower costs. The longer life obtained with the Tubothal® system, ensures highly reliable production and uninterrupted furnace operation.

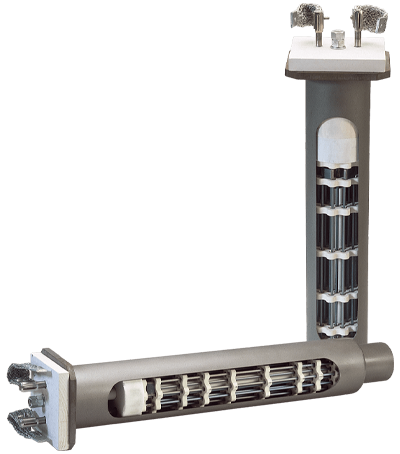

Tubothal® element assemblies are available in a wide range of standard diameters, to suit the sizes of tubes currently available. In principle, the length of an element is virtually unlimited, but the practicalities of packing, shipping and installation may impose restrictions on the usable length. Tubothal® elements are suitable for both horizontal and vertical installations. Normally, horizontal tubes are simply supported at both ends. With very long radiant tubes, it may be necessary to provide supports along the tube length.

Kanthal® APM rod has proved ideal for fabricating suitable support systems, hooks, etc.

Maximum design power outputs for all standard element diameters at different

furnace temperatures

Higher power output

Tubothal® elements will operate at a far higher power output than standard designs of radiant tube elements.

A single Tubothal® assembly may be capable of replacing up to three heaters of a more conventional design, leading to major savings in replacement and maintenance costs.

In other cases, a change to Tubothal®, combined with uprated power input to the existing furnace, has resulted in improved furnace capacity at a much lower cost compared to a completely new furnace.

Fitting a few Tubothal® assemblies in an existing furnace can in some cases increase productivity by over 50%. The power output for standard Tubothal® elements is a function of element diameter, effective heating length and operating temperature of the furnace. The diagram above illustrates suggested maximum design power outputs for all standard element diameters, at furnace temperatures between 800°C and 1100°C.

Power supply

Vertical and horizontal Tubothal elements.Although individual elements can operate at a voltage lower than that of the supply. In multiple element installations, groups of elements can be series – connected directly to the main voltage without the need of transformers. There is no significant aging of the Kanthal® APM elements, so a variable voltage supply is not required. On/off control can be used, but three-term control, using fast or slow, cycle fired thyristors, will ensure a more stable element temperature and a longer element life, as well as offering better control of the furnace temperature.

Vertical and horizontal Tubothal elements.Although individual elements can operate at a voltage lower than that of the supply. In multiple element installations, groups of elements can be series – connected directly to the main voltage without the need of transformers. There is no significant aging of the Kanthal® APM elements, so a variable voltage supply is not required. On/off control can be used, but three-term control, using fast or slow, cycle fired thyristors, will ensure a more stable element temperature and a longer element life, as well as offering better control of the furnace temperature.

Tubothal® benefits

- Very high power levels

- “Maintenance free”, longer service intervals

- Low ageing

- Low element weight

- Low thermal mass

- Standardized product for fast delivery and reliability

- Design flexibility

- Kanthal® powder metallurgy tubes can also be used for gas heated solutions