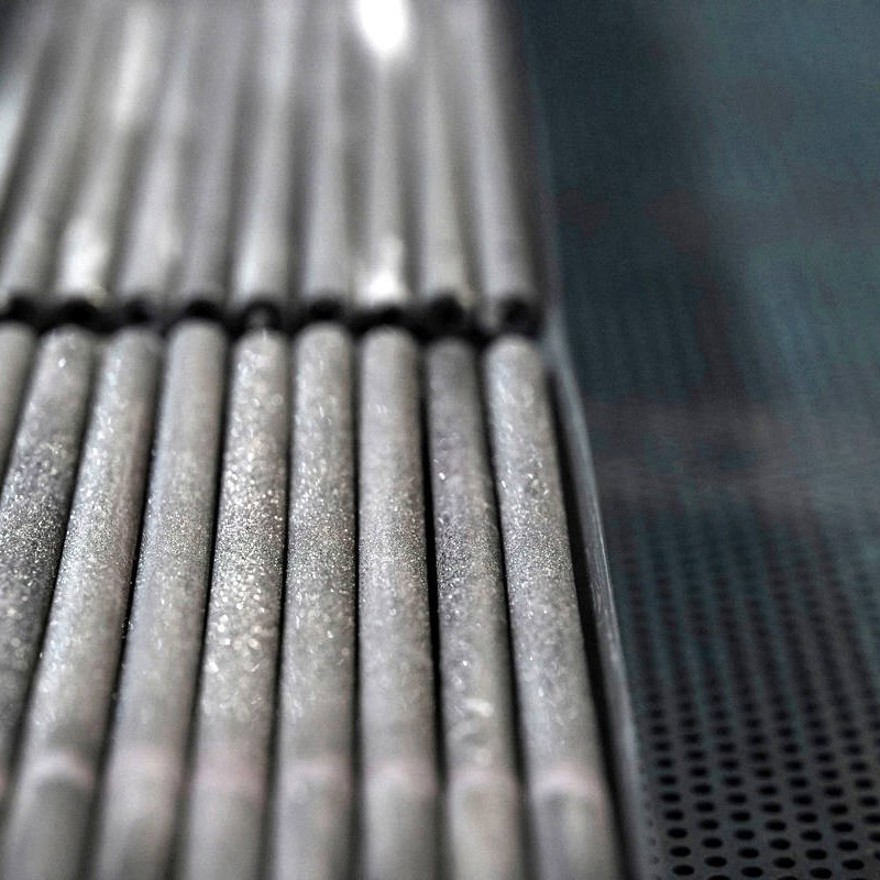

Globar® Glass Seal

Our Globar® Glass Seal for silicon carbide (SiC) heating elements has been specially developed for use in corrosive atmospheres and those with high water content, especially within the glass, electronics and precious metals industries.

Information

Globar® Glass Seal is part of the Globar® Precision family of state-of-the-art silicon carbide (SiC) heating solutions, each of which has been developed for use in specific atmospheres and conditions.

Globar® Glass Seal has been specifically designed for the very toughest operating conditions. It delivers longer element life, reduced need for maintenance, fewer shutdowns and enhanced quality and process stability, compared with standard products.

Globar® Glass Seal is interchangeable with existing products and can be applied to all heating element types within the Globar® range, making it suitable for both new and existing applications.

Protective Globar® Glass Seal adds many benefits

By choosing Globar® Glass Seal, customers will benefit from all the advantages offered by the product, which protects the element from chemical attack and particularly inhibits water vapor attack. The protective seal enables the element to withstand aggressive applications and delivers a product lifetime that can be up to three times longer than that of an unprotected element. It also reduces the need for replacement and therefore minimizes downtime while ensuring temperature uniformity for longer periods of time. This enables customers to improve yield and product quality from the furnace. in the furnace.

Globar® Glass Seal Advantages

- Top-of-the-range product for use in the toughest conditions

- Extended product lifetime: the protective seal enables the element to last up to three times longer than an unprotected product

- Able to withstand aggressive applications, corrosive atmospheres and those with high water content

- Specially designed for use in glass, electronics and precious metals segments

- Protective seal reduces maintenance needs and enables customers to extend service intervals

- Better productivity, longer life and less maintenance results in overall reduced manufacturing costs

- Delivers temperature uniformity for longer periods of time, resulting in enhanced product quality

- More robust product for reduced downtime, increased process stability and improved OEE (overall equipment effectiveness)

- Interchangeable with existing products

- Applicable to all Globar® SiC heating elements

Installation

Installation and technical support are provided by our experts throughout our global organization. The product allows customers to upgrade the performance of their furnaces without having to change electrical power supplies. Globar® Glass Seal can be installed in any suitable application, allowing customers to benefit immediately from enhanced performance.

Characteristics

10 key reasons for choosing Globar® Glass Seal

- Sealed to withstand chemical attack, corrosive atmospheres and water vapor

- Very robust

- Longer lifetime

- Reduced manufacturing costs

- Less maintenance and minimized downtime

- Improved customer product quality

- Increased productivity

- Enhanced process stability

- Improved overall equipment effectiveness

- Helps towards your long-term energy reduction and sustainability targets