Globar® heating elements

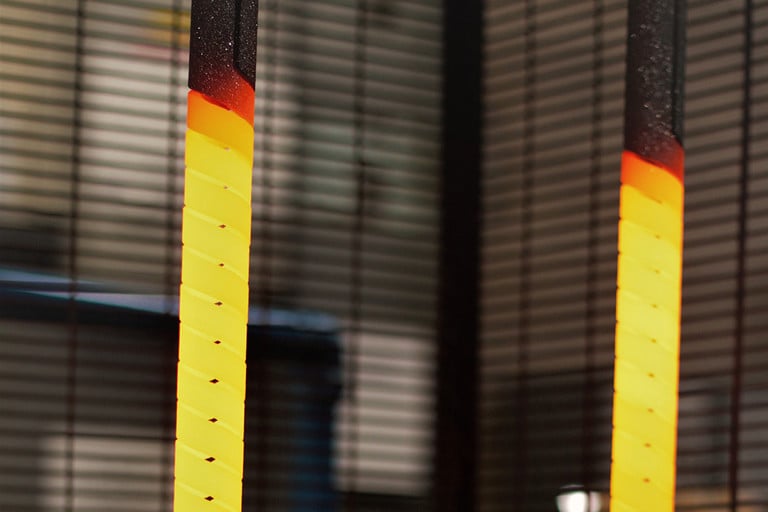

Silicon carbide (SiC) electric heating elements for element temperatures up to 1625°C (2927°F), available in a wide variety of standard sizes and geometries, or in customized designs to meet the specific needs of various processes and equipment.

Industries

Information

Geometry information

- Diameters from 10mm – 55mm

- Hot zones up to 4.2m

- Overall lengths from 100mm – 6m

Standard grades

| Grade | Description |

|---|---|

| Globar® SD | Elements suitable for most applications in which silicon carbide elements are used. Globar® SD SiC heating elements feature hot zones of recrystallized silicon carbide, optimized for resistance to oxidation and common process gases. Available in rod or multi-leg designs. |

| Globar® AS | A Dense recrystallised SiC material with approximately 20% porosity, a high Weibull modulus, much stronger than SD and our competitors’ products and particularly useful in applications that are cyclical, long span, or subject to strong mechanical vibration. |

| Globar® HD | SiC heating elements designed for the most challenging applications where conventional silicon carbide elements are unsuitable. Globar® HD SiC heating elements feature hot zones of high density, low permeability, reaction-bonded silicon carbide, which is highly resistant to oxidation, and to chemical attack by process volatiles and reactive atmospheres. Available in rod or multi-leg designs. |

| Globar® SG and SR | Tubular spiralled SiC elements made from Globar® HD material. |

Characteristics

Element configuration

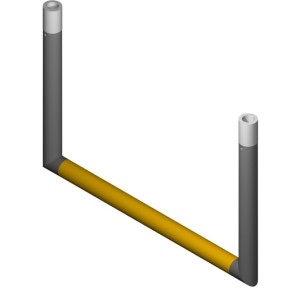

Type B: roof/lid heating orientation; limited space

Type U: Vertical or horizontal orientation; convenient connections

Type W: Float glass, standard; 3-phase element

Type SG: Spiral HZ, long life; aggressive applications

Type SR: Spiral HZ, long life; high temperature applications

Applications

Downloads

Related products

Other products that might interest you