U and W shaped radiant tubes

U and W shaped radiant tubes for tube temperatures up to 1,250°C (2,280°F). The Kanthal® program of radiant tubes includes nickel-chromium (NiCr) alloys or Kanthal® APM and Kanthal® APMT iron-chromium-aluminium (FeCrAl) alloys for extremely demanding environments, of combinations of the two material types.

Read more about Kanthal® APM and Kanthal® APMT FeCrAl alloys

Information

The flexibility in choice of material means that Kanthal® can offer the optimal tube design for practically any furnace atmosphere, process temperature and/or installation design. Our offer includes:

Radiant tubes for very high temperatures and severe conditions

Radiant tubes for tougher conditions at the burner leg

Radiant tubes for medium high temperatures

Compared Kanthal® alloys to other alloys:

| Material | In air / oxidizing | Oxidizing sulphur | Reducing sulphur | Carburizing | Nitriding |

|---|---|---|---|---|---|

| ASTM 310 | 0 | 0 | 0 | 0 | 0 |

| 253 MA1) | + | + | ++ | + | 02) |

| 353 MA1) | + | - | 0 | ++ | ++ |

| Kanthal® APM | ++ | ++ | ++++ | +++ | +3) |

| Kanthal® APMT | ++ | ++ | ++++ | +++ | +3) |

1) 253 MA and 353 MA are trademarks owned by Outokumpu OY

2) Nitriding may occur at very low dew point (<-60°C/-51°F)

3) Severe nitriding may occur at low dew point (<-20°C/-29°F)

Characteristics

The flexibility in choice of material means that Kanthal can offer the optimal tube design for practically any furnace atmosphere, process temperature and/or installation design. Our offer includes:

Radiant tubes for very high temperatures and severe conditions

Radiant tubes for tougher conditions at the burner leg

Radiant tubes for medium high temperatures

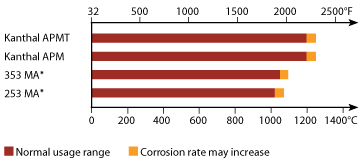

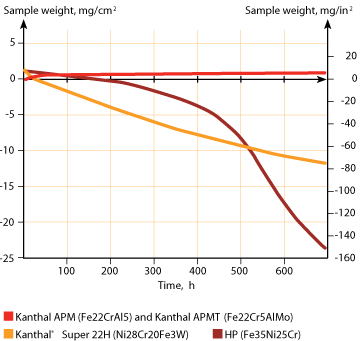

Oxidation properties at 1,100ºC (2,040ºF)

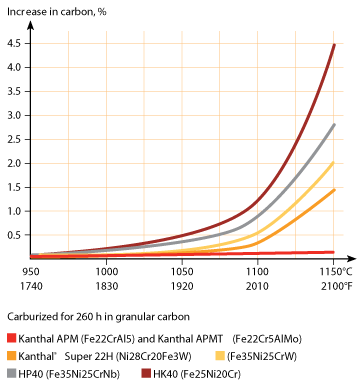

Carburization rate for various alloys