Daniel Burton, Business Development Manager, KanthalIn aluminum production, filter units are vital for removing impurities from the final product. Before coming into contact with molten aluminum, each filter needs to be completely dried and preheated in order to avoid thermal shock or blockages caused by cooled aluminum.

Daniel Burton, Business Development Manager, KanthalIn aluminum production, filter units are vital for removing impurities from the final product. Before coming into contact with molten aluminum, each filter needs to be completely dried and preheated in order to avoid thermal shock or blockages caused by cooled aluminum.

“Traditionally this has been done using gas burners heaters, however they have a number of disadvantages,” says Daniel Burton, Business Development Manager, Kanthal. “Their thermal efficiency is quite poor, and they can also produce water vapor – which is something we need to remove in the drying process to eliminate any risk of explosion.”

In addition, gas burners generate carbon emissions and other exhaust gasses, which are not only bad for the environment but can also contribute to a hazardous workplace in the factory.

Same performance but with increased efficiency

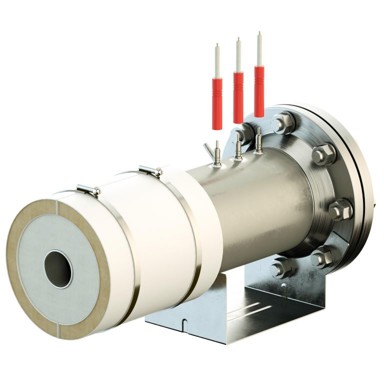

The Kanthal® Flow Heater can provide the same temperatures and control as gas burners, but because it’s powered by electricity, its efficiency is vastly improved.

The Kanthal® Flow Heater can provide the same temperatures and control as gas burners, but because it’s powered by electricity, its efficiency is vastly improved. Virtually all the heat produced is used on the filter instead of being lost in exhaust gasses, and no water vapor is produced in the preheating process.

“By switching from gas to electric heating, you can greatly reduce the CO2 emissions from the process, as well as eliminate all the other harmful pollutants like nitro oxide,” adds Daniel Burton. “Combined with the reduced risk of explosion and lower noise levels, this also contributes to a far safer and more pleasant environment inside the factory.”

Three benefits to using Kanthal® Flow Heater for preheating filter units in primary aluminum production

- More efficient. Thermal efficiency with electric heating can be as high as 80-90 percent (compared to 30-40 percent with gas burners), which will reduce energy consumption by around 50 percent.

- No water vapors. Electric heating will not cause water vapor to form, making the drying and preheating process more efficient and safer.

- No emissions. Switching from gas burners to electric heating will greatly reduce CO2 emissions as well as eliminate all other harmful exhaust gasses.

Connected products

Here you can find the Kanthal product offering

Learn from our experts

Our latest articles