Jinmoo Lee, Sales Manager, Kanthal KoreaAnode material is a vital component in the production of lithium-ion batteries, with its quality having a major impact on the efficiency and lifetime of the final product. Until recently, many lithium-ion battery producers sourced anode material from external suppliers, but increasingly they are investing in their own manufacturing capabilities.

Jinmoo Lee, Sales Manager, Kanthal KoreaAnode material is a vital component in the production of lithium-ion batteries, with its quality having a major impact on the efficiency and lifetime of the final product. Until recently, many lithium-ion battery producers sourced anode material from external suppliers, but increasingly they are investing in their own manufacturing capabilities.

“The importance of anode material is becoming bigger and bigger as manufacturers try to achieve the highest quality,” says Jinmoo Lee, Sales Manager for Kanthal Korea. “Because of the high demand for lithium-ion batteries, anode manufacturing is basically continuous, so it is critical that the manufacturing processes are reliable.”

An industry in transition

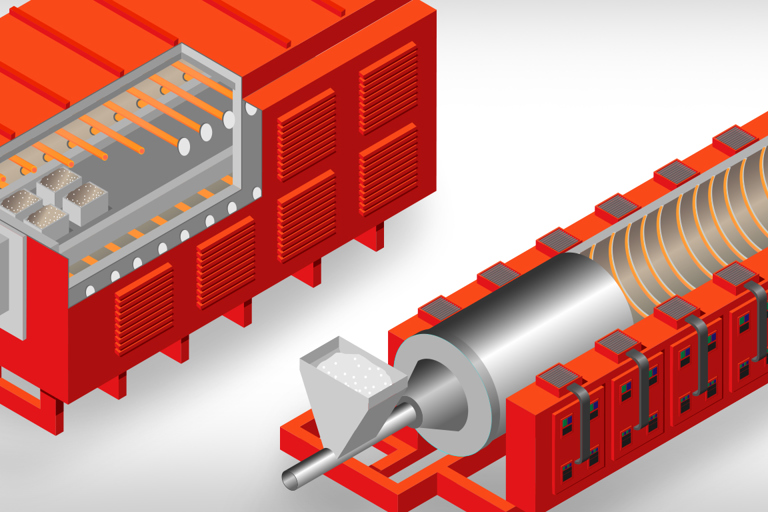

Graphite, both natural and artificial, is a common source for anode material, which is produced using roller kilns. One key challenge in this process is the high amount of carbon in the atmosphere, which has a detrimental effect on the heating elements and typically limits their lifespan to three to four months. As a result, many manufacturers are increasingly turning to silicon-based anode material. Because this type of material is so flammable, however, it has to be produced using rotary kilns.

From a manufacturer’s perspective the most important factors are long life for heating elements and minimal maintenance. The less production is disrupted, the better.

“The situation is very uncertain at the moment, because every company has its own preference when it comes to technology,” says Jinmoo Lee. “But regardless of the material base, from a manufacturer’s perspective the most important factors are long life for heating elements and minimal maintenance. The less production is disrupted, the better.”

Working with experienced partners

With the whole industry still learning about the most efficient production methods for anode material, Kanthal is drawing on its technologies and expertise to find the best heating solutions.

For graphite-based anode production, Kanthal’s Globar® HDP SiC heating elements can be used in roller kilns, where they have proven to last more than eight months – twice as long as conventional heating elements. This is due to their glazed, high-density material, which makes them more durable. For silicon-based anode production, where temperature demands are lower, Kanthal can offer Tubothal® metallic elements.

However, one of the biggest advantages of working with Kanthal is its vast experience and expertise and comprehensive technical support.

“Not only can we supply a reliable heating solution, but we can also help custom-design the heating elements to suit each customer,” says Jinmoo Lee. “This is because of a long history working with heating solutions, which is unmatched in the industry. Together with our ongoing technical support, this can help manufacturers achieve longer lifetimes in their heating elements and fewer stops for maintenance.”

Three benefits to using Kanthal heating solutions for anode material manufacturing

- Longer element lifetimes. Up to twice as long with Globar® HDP SiC heating elements in graphite-based anode material production.

- Custom designs. Tap into Kanthal’s vast experience and expertise to custom-design a heating element to suit your process.

- Global technical support. Continuous support to ensure reliable and maintenance-free operation.

Connected products

Here you can find the Kanthal product offering

Learn from our experts

Our latest articles