Sachin Pimpalnerkar, Global Product Manager, KanthalIt’s the party trick of electric car ownership: lifting the hood of the vehicle to reveal, well, nothing.

Sachin Pimpalnerkar, Global Product Manager, KanthalIt’s the party trick of electric car ownership: lifting the hood of the vehicle to reveal, well, nothing.

Where thousands of moving parts under high temperature and pressure endured millions of revolutions – nothing. And where hundreds of user and mechanic hours would be spent checking, refilling, draining and replacing – nothing.

The same party trick awaits refiners ordering new, electrically heated acid roasting kilns in the burgeoning market for lithium carbonate or lithium hydroxide, says Kanthal Global Product Manager Sachin Pimpalnerkar.

There’s just a lot less moving parts when you switch to an electric installation. Like an electric car motor, it's just a lot simpler.

“There’s just a lot less moving parts when you switch to an electric installation,” he adds. “Like an electric car motor, it's just a lot simpler.”

Simple and modular

Gone are the kiln’s gas-fired burners. Gone are the ducts. The dampers and blowers are no longer needed. The arrays of sensors used to ensure sufficiently complete combustion – gone.

On a rotary tube with a diameter of three to five meters and a length of perhaps 60 meters, it’s like replacing a tennis-court-sized thicket of air and gas pipes.

Kanthal’s Fibrothal® heating modules, which replace the above equipment, are simple and electric. Yet this simplicity is deceptively functional. The vacuum-formed, ceramic fiber linings are low in thermal mass and conductivity. Their snug shape also partially embeds the wire elements, allowing for a maximum element temperature of 1150 Degrees C (2,100 Degrees F).

The use of vacuum forming, which has been employed in the Fibrothal® product line since 1978, enables the heating elements to be shaped to encircle a segment of the heating chamber. Additional modules are added as required, depending on the length of the kiln.

This simplicity means a much-reduced risk of equipment failure and operator error, and the technology has been proven in many other applications and environments over decades.

Local environmental benefits

Apart from the simplicity, it is the benefits to the environment that are driving the interest in electrically heated acid roasting.

“There has of course been a lot of focus on the fact that you can power an electric kiln with renewably generated electricity and achieve near to zero operating CO2 emissions from the plant,” Pimpalnerkar says, “but you also get benefits in the local environment – for the workforce and the local area.”

NOx emissions, which are a cause of respiratory sickness and a key focus of environmental regulators in many jurisdictions, are eliminated in the electric kiln technology.

In environmentally conscious jurisdictions, authorities will resist permitting a new gas-fired kiln near population centers, where its emissions will add to existing pollution emitted by diesel vehicles or vessels entering city ports. Cities in many European countries already surpass mandated emissions levels for NOx.

Reducing CO2 emissions

On the other hand, the levels of greenhouse gas emissions (CO2) from battery manufacturing, where cathodes and anodes are thought to account for some 40 percent of emissions, provide a reason to actually site plants in these kinds of developed economies. That’s because often it is these countries that have come furthest in developing low-carbon power generation.

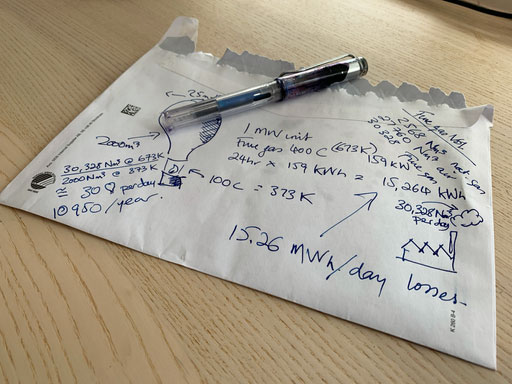

Overall, battery manufacturing relies overwhelmingly on electricity, and the carbon intensity of generation varies greatly. Chinese power generation, for example, was estimated in 2017 to generate 20 times the carbon emissions of Sweden and three times those of Brazil. The impact on overall CO2 emissions from battery manufacturing were calculated against a baseline site at –60 percent for a Swedish facility, compared with +30 percent to +70 percent for a factory located in China, Poland or India. Sachin Pimpalnerkar got out his pencil and explained on the back of an envelope how the high volume of flue gas leaving a gas-fired kiln sharply reduces the thermal efficiency of a typical 4 MW unit.

Sachin Pimpalnerkar got out his pencil and explained on the back of an envelope how the high volume of flue gas leaving a gas-fired kiln sharply reduces the thermal efficiency of a typical 4 MW unit.

As some manufacturers consider integrating manufacturing, these relative environmental benefits may create a cumulative case to switch from gas to electrically heated acid roasting of spodumene.

“Put together, you get a simpler and more thermally efficient technology, and environmental considerations tend to support siting it where the carbon intensity of electricity is low,” Pimpalnerkar says. “Interestingly, this is also where new mineral deposits are being discovered and where the electric car industry is increasingly incentivized to base its production.”

Benefits from using Fibrothal® heating modules in acid roasting of spodumene

- Low thermal mass and low conductivity resulting in higher energy efficiency

- Fast and easy to install and replace

- High power concentration

- Flexibility of shapes like half cylinders, part cylinders and modular construction mean optimized custom designs.

Kanthal as a partner in electrifying your kiln

- Reliability – we have a 90-year history in converting gas-heated furnaces to electrically heated ones

- Kanthal provides an extensive level of technical support

- Strong global presence – a speaking partner in your chosen region

- Deep expertise in electrode active material

Connected products

Here you can find the Kanthal product offering

Learn from our experts

Our latest articles