Fibrothal® prefabricated heating modules

Fibrothal® heating modules play a central role in electrifying large-scale industrial heating processes as they are specifically designed for high-temperature applications. These modules consist of metallic heating elements encased in vacuum-formed ceramic fiber (KF) insulation that can withstand temperatures up to 1,350°C (2,460°F). Fibrothal® heating modules are quick to install, and their modular setup makes them easy to tailor to specific customer needs. The lightweight design of Fibrothal® heating modules is pivotal in modernizing industrial furnaces and significantly reducing energy consumption.

Key features

- Lightweight design

- Heating and insulation in one

- High-temperature applications

- High insulation properties

- Customizable

- Wide range of applications

- Fast installation and replacement

- Energy saving

Types of Fibrothal® heating modules

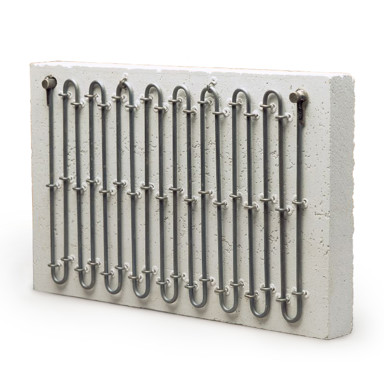

Modules with embedded heating

The heating element is directly incorporated into the module and requires no additional mountings.

- Can be used for almost all furnace layouts.

- In addition to panels for furnaces with flat walls, there are a variety of module designs for cylindrical surfaces.

- Maximum element temperature up to 1,150°C (2,102°F).

RAC tubes

Embedded but virtually free-radiating heating element.

- Self-supporting and/or self-stabilizing inside the furnace body.

- Maximum element temperature up to 1,300°C (2,372°F).

ROB in panel and shell design

Modules with built-in mounting system and meander-shaped heating elements of round wire, the element legs mainly running next to each other in V-form.

- Both Kanthal® and Nikrothal® alloys can be used.

- Element temperature up to 1,300°C (2,372°F).

- Possible to change the heating element.

- Long heating element length over several modules is possible, therefore far fewer terminals are required.

Meanderthal II

Heating element mountings consist of metallic hairpin-shaped parts, which are anchored in the ceramic fiber module.

- No limitation on the installation position.

- Suitable for tilting, roof heating, and round furnaces.

- Maximum element temperature up to 1,300°C (2,372°F).

Meanderthal III

Heating element mountings consist of metallic rod support and metallic holders, anchored in the ceramic fiber module.

- Elements can be replaced.

- Tilting of furnaces up to 90° is possible.

- Also suitable for round furnaces.

Special tube modules

These modules, usually multi-zone, are similar in design to the RAC tubes.

- Can also be supplied with a sheet metal shell.

- Kanthal® A-1, AF, or APM alloys are used.

- High-temperature uniformity.

- Precise temperature profiles can be achieved.

- Can be installed in any position.

Muffles

Monoblock ceramic fiber modules with embedded heating elements made of Kanthal® alloys

- Can be used for laboratory and small chamber furnaces.

- Can be heated on up to four sides.

- Maximum element temperature up to 1,150°C (2,102°F).

- Matching door modules can be supplied.

- Short assembly and heating up times.

Insulating parts

Can be supplied in the same dimensions as the special heating modules.

- FibroSiC unsupported roof modules.

- Designed to achieve self-supporting, easy-to-assemble roof insulation.

- Combination of ceramic fiber, insulation modules, and SiC tubes.

- Unsupported up to 2,200 mm at furnace temperature up to 1,200°C (2,192°F).

Here is a step-by-step guide that walks us through the entire process, from understanding the different types of Fibrothal® heating modules to replacement instructions.

Information

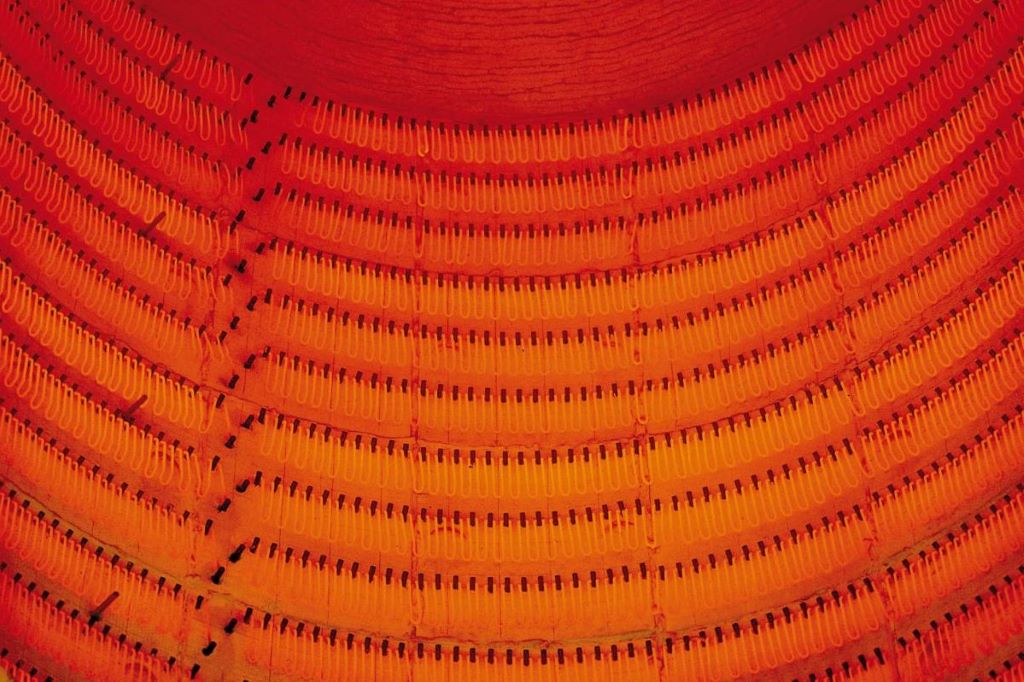

The construction method of Fibrothal® heating modules ensures accurate positioning of the coils and eliminates the distortion or other problems connected to the conventional open coil elements in grooves or on tubes. Fibrothal® heating modules also provide major energy savings in several applications.

Characteristics

The low thermal mass and thermal conductivity of the ceramic fiber furnace linings mean that you can build industrial furnaces which, depending on the type and mode of operation, contribute significantly to energy saving, higher output and better availability.

In the electrically heated furnace, however, it is very expensive and time consuming to combine ceramic fibers, such as blankets or folding blocks, with electric heating elements. This has led to the product concept which we introduced to the market in 1978 under the trademark Fibrothal®.

Today the Fibrothal® trademark covers a family of products consisting of vacuum-formed ceramic fiber components, with or without electric heating elements.

Applications

Related products

Other products that might interest you