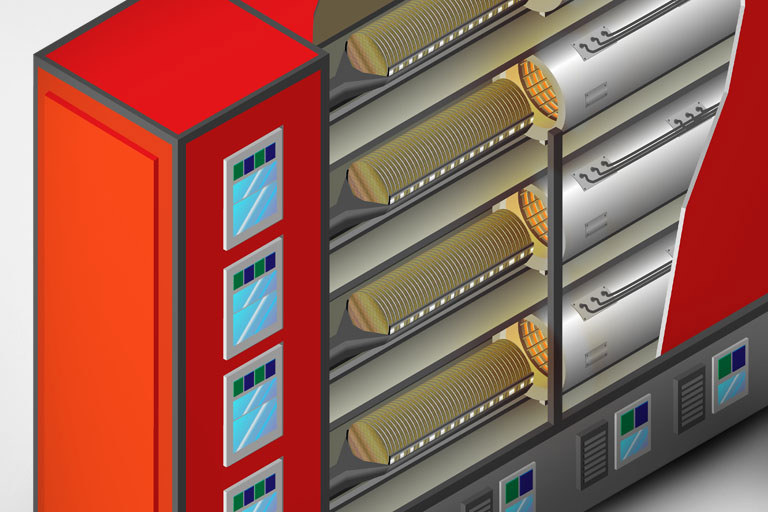

Atmospheric processes play a crucial role in the semiconductor industry, enabling the fabrication of high-performance devices. These processes serve diverse purposes, including the controlled diffusion of dopants into materials and the optimization of crystal structures for improved device reliability and overall quality.

The process in short

Atmospheric processes, such as annealing and oxidation, play a pivotal role in enhancing the structural integrity of semiconductor materials. Annealing optimizes crystal structures, relieving stress and activating dopants, thereby contributing to improved device reliability and overall quality. Oxidation creates protective silicon dioxide layers, enhancing insulation properties and fortifying the reliability of semiconductor devices.

Setting the industry standards

Beyond their role in structural optimization, atmospheric processes are vital for high-temperature applications exceeding 1,150°C (2,102°F). These processes are essential for achieving specific material transformations crucial for desired device characteristics and performance. The significance of atmospheric processes also lies in their ability to provide uniform and precise conditions throughout semiconductor manufacturing, which is critical for semiconductor devices that demand high precision in their electrical characteristics.

The significance of temperature uniformity cannot be overstated.

Tyke Johnson, Product Line Manager, Kanthal."In semiconductor manufacturing, process control emerges as the architect of precision, where meticulously crafted recipes guide furnaces to produce the desired outcomes,” says Tyke Johnson, Product Line Manager at Kanthal. “Simultaneously, heating technology takes the spotlight. The significance of temperature uniformity cannot be overstated, as variation holds the potential to impact the entire outcome, underlining the delicate balance required in this high-precision industry."

Tyke Johnson, Product Line Manager, Kanthal."In semiconductor manufacturing, process control emerges as the architect of precision, where meticulously crafted recipes guide furnaces to produce the desired outcomes,” says Tyke Johnson, Product Line Manager at Kanthal. “Simultaneously, heating technology takes the spotlight. The significance of temperature uniformity cannot be overstated, as variation holds the potential to impact the entire outcome, underlining the delicate balance required in this high-precision industry."

Johnson highlights that as customers increasingly demand longevity, tight uniformity, and high purity in semiconductor manufacturing, Kanthal has positioned itself at the forefront of the industry, leveraging a unique set of advantages. The cassettes produced by Kanthal are crafted with distinct characteristics to ensure longevity and precise, repetitive fits, meeting immutable recipes that set the standard.

Let's delve into some key atmospheric processes in semiconductor manufacturing:

High-Temperature Oxidation:

High-temperature oxidation is a crucial step where semiconductor materials, often silicon, undergo controlled exposure to elevated temperatures in the presence of oxygen or other oxidizing agents. This results in the formation of a thin layer of silicon dioxide on the surface of the material.

The oxide layer serves as an insulating barrier and can be strategically incorporated into the semiconductor device's structure to enhance its electrical and thermal properties.

High-Temperature Drive:

The high-temperature drive involves subjecting semiconductor materials to elevated temperatures to encourage the movement of dopants within the material. This diffusion enhances the electrical characteristics of the semiconductor, influencing factors like conductivity.

The high-temperature drive is employed to fine-tune the electrical properties of the semiconductor, optimizing its performance in electronic devices.

Oxidation:

Oxidation involves exposing semiconductor materials to oxygen or other oxidizing agents at controlled temperatures. This leads to the formation of oxide layers on the semiconductor surface.

Similar to high-temperature oxidation, the purpose is to create insulating layers, providing improved electrical insulation and protection for the semiconductor material.

Anneal:

Annealing is a heat treatment process where semiconductor materials are exposed to controlled temperatures to induce changes in their crystal structures. This helps relieve stress, activate dopants, and optimize the overall structural integrity of the material.

The primary purpose of annealing is to enhance the electrical and mechanical properties of the semiconductor, contributing to improved device reliability and performance.

The list of processes mentioned above is by no means exhaustive, as semiconductor manufacturing involves a myriad of intricacies and steps to achieve desired outcomes.

Read more

Our latest articles