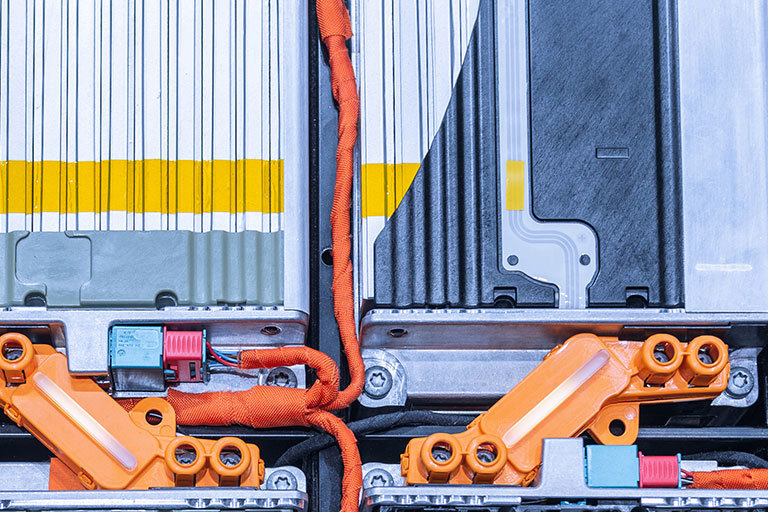

As with all industrial high-temperature production processes, the challenge for furnace operators is to maximize energy efficiency and productivity, while ensuring a consistent, high-quality cathode material.

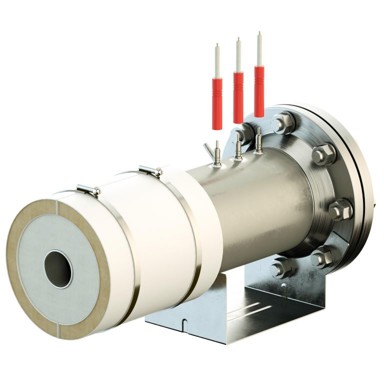

Depending on the type of furnace, Globar® SiC heating elements and Fibrothal® heating modules can be used in cathode material production, where they offer the advantage of being able to control temperatures precisely. The Kanthal® Flow Heater can also be used to introduce heated gas into the furnace, which can help increase productivity even further.

Connected products

Here you can find the Kanthal product offering

Learn from our experts

Our latest articles