Search

633 hits

633 hits on ”all pages” in entire website

A stronger connection

A STRONGER CONNECTION After making a number of custom-made modifications to its Globar® SiC heating elements, Kanthal was able to help Toyota Motor Manufacturing Poland increase the lifespan of its elements to an average of two years from seven months. Challenge Located across two plants

Nikrothal® 60

Nikrothal® 60 Wire Nikrothal® 60 wire is an austenitic nickel-chromium alloy (NiCr alloy) for use at temperatures up to 1150°C (2100°F). The alloy is characterized by high resistivity, good oxidation resistance and very good form stability. It has good ductility after use andNikrothal® 80

Nikrothal® 80 Wire Nikrothal® 80 wire is an austenitic nickel-chromium alloy (NiCr alloy) for use at temperatures up to 1200°C (2190°F). The alloy is characterized by high resistivity, good oxidation resistance and very good form stability. It has good ductility after use andKanthal® LT

Kanthal® LT is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) for use at temperatures up to which 1100°C (2010°F). The alloy is characterized by moderate resistivity and good oxidation resistance. Kanthal® LT is typically used in home appliances. A ferritic iron-chromium-aluminiumKanthal® AF

Kanthal® AF Wire Kanthal® AF wire is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) for use at temperatures up to 1300°C (2370°F). The alloy is characterized by excellent oxidation resistance and very good form stability resulting in long element life. Kanthal®Kanthal® AE

Kanthal® AE Wire Kanthal® AE wire is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) with exceptional form stability and service life in elements with large coil to wire diameter ratio. It is suitable for use at temperatures up to 1300ºC (2370ºF). Kanthal® AE hasKanthal® A-1

Kanthal® A-1 Wire Kanthal® A-1 wire is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) for use at temperatures up to 1400°C (2550°F). The alloy is characterized by high resistivity and very good oxidation resistance. Typical applications for Kanthal® A-1 are electricalKanthal® D

Kanthal® D Wire Kanthal® D wire is a ferritic iron-chromium-aluminium alloy (FeCrAl alloy) for use at temperatures up to 1300°C (2370°F). The alloy is characterized by high resistivity and good oxidation resistance. Kanthal® D is used in home appliances and industrial furnaces.New 60 kw flow heater for high power demands

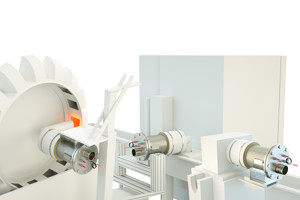

Discover Kanthal's new 60 kW flow heater for high power demands. Ideal for aluminum and glass industries, offering superior temperature control and efficiency

A powerful tool

A POWERFUL TOOL Heat treatment is an essential post-processing step in additive manufacturing to tailor the material in the produced part to specific needs and requirements. The path to success is finding the right combination of material and heat treatment. Additive manufacturing (AM) lets us