Search

72 hits

72 hits on ”all pages” in Industries

Ladle preheating

The future is electric – not least when it comes to ladle preheating. As businesses around the world seek out safer, more efficient climate-smart solutions, electric heating is on the rise. So says Olivier Tanguy, Business Development Manager with Kanthal. Electric ladle preheating solutions

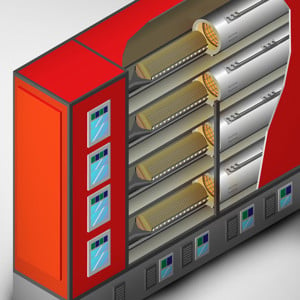

LPCVD: Precision Engineering for Advanced Semiconductor Devices

Diffusion cassettes for LPCVD processes Widely embraced in the semiconductor industry, LPCVD finds applications in depositing materials like silicon nitride, silicon dioxide, and polysilicon. Its controlled nature and ability to achieve precise thickness and uniformity make LPCVD a cornerstone

The benefits of electric heating over gas in roller hearth furnaces

In roller hearth furnaces, electric heating increases temperature control while also significantly reducing CO2 emissions and improving energy efficiency.

How Atmospheric Processes Shape High-Performance Semiconductor Devices

Atmospheric processes in semiconductor manufacturing shape high-performance devices by controlling oxidation, annealing, and high-temperature drive for tailored characteristics.

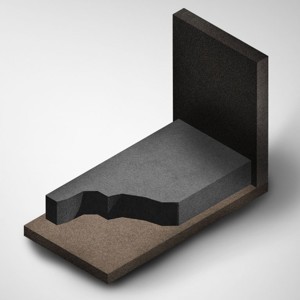

Tundish preheating

Electric solutions have never been more in demand – and word of their growing popularity has reached the metallurgy sector. When it comes to tundish preheating, electric heating solutions improve sustainability and energy efficiency, while minimizing material losses and interruptions. In this

How electric heating can help foam glass manufacturers reach their full potential

With recycled materials and an environmentally friendly process, the foam glass manufacturing process contributes to a more sustainable world.

Continuous furnaces

Whether it’s annealing and galvanizing lines or a roller hearth furnace, electric heating can make the process cleaner and more efficient, while greatly reducing maintenance and repairs. Whether it’s annealing and galvanizing lines or a roller hearth furnace, electric heating can make the

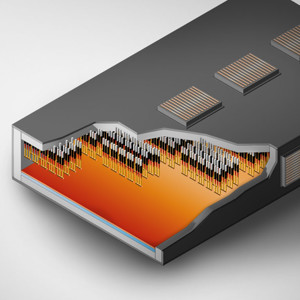

Foam glass

With its focus on recycling glass and turning it into insulation, the foam glass industry is already on the right path. Still, CO2 emissions are prominent because of the common use of gas burners which offers poor thermal efficiency at around 30 percent – compared to 90 percent thermal

Long life heating elements for long-life float baths

To achieve an exceptionally smooth finish on flat glass, the float bath process is a necessary step in flat glass manufacturing.

A cleaner, quieter heating solution for annealing lines

By using electric heating instead of gas for annealing processes, steel producers can significantly reduce energy consumption and CO2 emissions.