Search

633 hits

633 hits on ”all pages” in entire website

Can heating element choice improve furnace efficiency?

CAN THE CHOICE OF HEATING ELEMENT IMPROVE THE ENERGY EFFICIENCY OF A FURNACE? The choice of heating element has a significant impact on the overall energy efficiency of a furnace, but it is not the only factor. In fact, if other considerations are not taken into account, the savings achieved

Custom Electric Manufacturing to merge into Kanthal

Custom Electric Manufacturing was acquired by Sweden-based Kanthal in 2018 and will now go to market under the Kanthal brand. The transition will be effective as of January 1, 2021. Custom Electric Manufacturing (CEM) will as of January 1, 2021 be fully integrated into Kanthal. According to Jon

Reliable heating elements improve cathode production

RELIABLE HEATING ELEMENTS IMPROVE CATHODE PRODUCTION Kanthal’s Globar® SiC (silicon carbide) heating elements have been specifically engineered for high-tech applications with tough conditions, such as cathode material production. The substrate’s unique microstructure makes it more reliable

Multilayer ceramic capacitors

Manufacturing of multilayer ceramic capacitors requires several heat intensive processes. Casting, binding and sintering are common processes in this industry which pose their own challenges. For Powder metal sintering and ferrite sintering, the furnace which material passes through is a

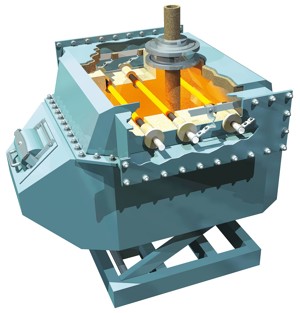

Casting of automotive parts

Electric heating elements and prefabricated heating modules for casting of for example aluminium, magnesium and steel.

Superthal® SHC

Superthal® SHC used for horizontal and vertical furnace applications. Specially designed to meet the requirements of each application in terms of power and dimensions. Max. operating temperature 1550ºC (2820ºF).

Commercial applications

Our resistive materials can be used for commercial applications similar to home appliances. Rather than low powered, smaller units, heating elements can be scalled for large applications such as office buildings, highrises, and and more. Similar to white goods, these larger scale applications

White goods

White goods are household ammenities used which are typically larger than simply appliances. These are higher powered and typically use our material for resistive heating. The Kanthal® offering is commonly found in white goods for: Refrigerators Dishwashers Washing machines home heating

Industrial ceramics

While ceramics can be thought of as decorative tableware, there are many functional applications that can be found using ceramics. Many different industries seek out this material because of its thermal, electrical, and even optical properties. The Kanthal® offering supports the industrial

Consumer ceramics

The consumer ceramics application can range from small to large across many different diciplines. We supply material from pottery kilns to casting furnaces and everything in between. We have supported many different applications with both the Kanthal® and Nikrothal® grade alloys. For