THE CHALLENGE

At the Nissan plant in Barcelona, Spain, where the heat treat-ment of transmission parts is centred, problems arose when two radiant tubes in a furnace failed to operate as expected. Tube failures meant that up to three days production were lost each time in that furnace.

Short tube life causes production problems

The heat treatment shop operates, among others, two gas fired Ipsen double-chamber furnaces with 24 radiant tubes in each. The tubes are installed vertically with the burners at the bottom. The process is carried out at 910–920°C (1670–1690°F) in a nitrogen-methanol atmosphere with a carbon potential of 0.85–1.2%. Production runs continuously with planned maintenance stops three times per year.

The service life of the nickel-chromium tubes originally installed was not satisfactory, sometimes lasting only four months. If one tube failed, production could continue with higher power in the remaining tubes, but with two failures, production must stop for three days to cool down, for tubes to be replaced and heated up again. Alternative nickel-chromium tubes were tested without much improvement.

THE SOLUTION

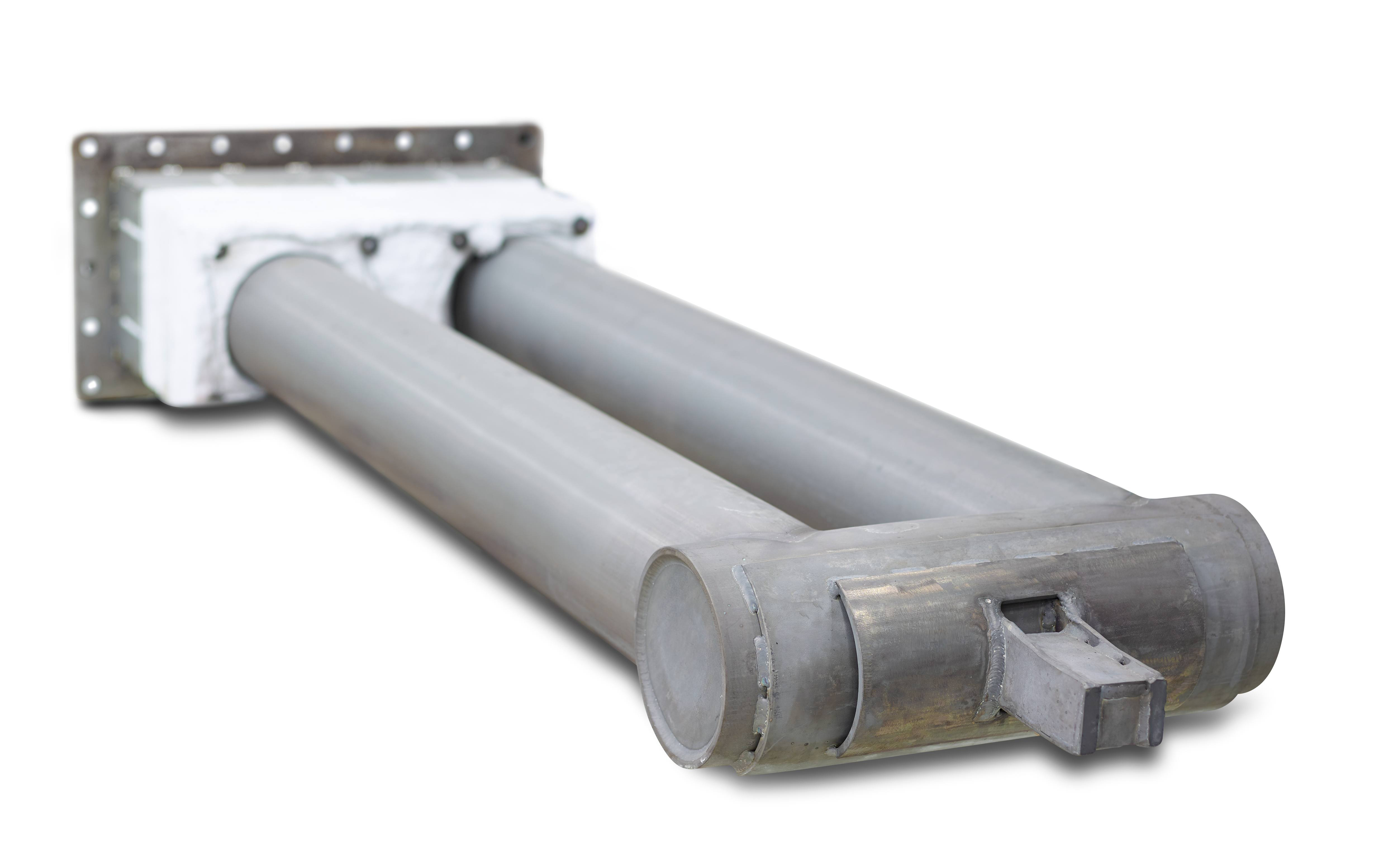

By installing Kanthal® APM tubes, production now runs in accordance with production schedules without interruption. Kanthal® APM tubes solved the problems Four Kanthal® APM tubes were installed as a trial in the first chamber of one furnace, where the temperature variations and power requirements are higher than in the second chamber, and consequently tube failures more frequent.

THE RESULT

The lifetime of all individual tubes was recorded. After 18 months of trouble-free operation a decision was made to change all the tubes in the first chamber to Kanthal® APM. Later, all the tubes in the second furnace were changed to Kanthal® APM. The high carbon potential was not a problem. The carbon did not penetrate the Kanthal® APM tubes at all.

The result is a substantial improvement in furnace reliability. There have been no production stops, and production runs completely as scheduled. The overall lifetime of the Kanthal® APM tubes is about 4–5 years.

Kanthal® APM radiant tubes are manufactured in a powder metallurgy process of the same material as the well-known Kanthal® A-1 resistance heating alloy.

Maximum temperature is 1425°C (2600°F), limited to 1250°C (2280°F) in tubes.

The dense oxide on the surfaces protects the tube from further oxidation and from carbon pick-up.

Dimensions of the tubes in the Nissan furnaces are (L × outer diam. × wall thickness) 1875 × 87 × 5 mm (74 × 3.4 × 0.2 in.).