Search

170 hits

170 hits on ”all pages” in Knowledge hub

Linda Widigsson about leadership and career choices

Linda Widigsson, Kanthals CFO, is on this year’s prestigious mining and steel industry list ”40 over 40”. The achievements are results of a career based on taking on fun and interesting roles.

Delivery forms appliance wire

In order to avoid transport damage all goods are carefully packed in cardboard boxes or wooden cases, with suitable internal protection. Content: Ribbon Rods Other resistance alloys - Cuprothal® RESISTANCE HEATING ALLOYS – KANTHAL®, ALKROTHAL®, NIKROTHAL® AND NIFETHAL® Wire

Standard tolerances

Standard tolerances for wire and ribbon are given below. Size tolerances do not apply to material manufactured to resistance tolerances and vice-versa. Tolerances on electrical resistance RESISTANCE OF WIRE AT 20°C (68°F) Diameter ≤ 0.127 mm (0.005 in) ± 8%. All dimensions > 0.127

Inspiring stories

Success stories and inspiring insights from the industry storyVideos

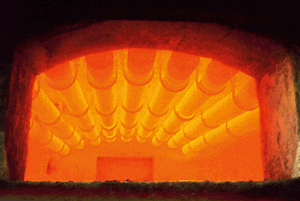

videoTubothal®

TUBOTHAL® – THE MOST POWERFUL METALLIC ELEMENT SYSTEM Tubothal® is an ideal electric element used in combination with powder metallurgy tubes because of its great advantages, such as – very high power – long life – low weight – easy to design to existing power controls and supply. Combined

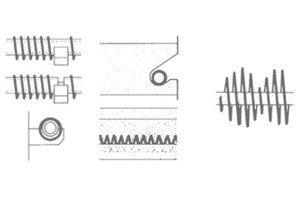

Key data for Kanthal® elements

Wire elements Element systems Spiral Spiral Porcupine Rod over bend Corrugated Looped Supports Ceramic tubes Grooves Ceramic tubes Metallic rods Metallic staples Ceramic tubes Material Sillimanite Chamotte grade 28 Sillimanite Kanthal® APM U-shaped Kanthal® nails Sillimanite Max.

Operating life and maximum permissible temperature

When heated, resistance heating alloys form an oxide layer on their surface, which prevents further oxidation of the material. To accomplish this function the oxide layer must be dense and resist the diffusion of gasses. It must also be thin and adhere to the metal under temperature

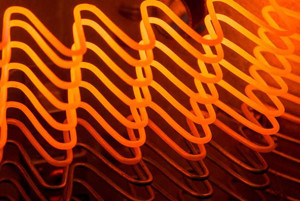

Element surface load

Since Kanthal® alloys can be operated at higher temperatures than Nikrothal® alloys, a higher surface load can be accepted without jeopardizing element life. Element design is also of great importance. The more freely radiating the element form, the higher the maximum surface load can

Design factors

Content: Operating life Oxidation properties Corrosion resistance Maximum wire temperatures as a function of wire diameter when operating in air Operating Life The life of the resistance heating alloy is dependent on a number of factors, among them the most important are: temperature