Search

632 hits

632 hits on ”all pages” in entire website

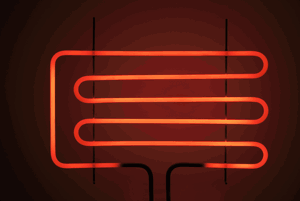

Tubothal®

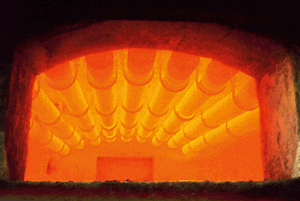

TUBOTHAL® – THE MOST POWERFUL METALLIC ELEMENT SYSTEM Tubothal® is an ideal electric element used in combination with powder metallurgy tubes because of its great advantages, such as – very high power – long life – low weight – easy to design to existing power controls and supply. Combined

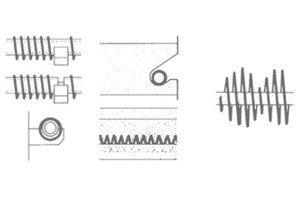

Key data for Kanthal® elements

Wire elements Element systems Spiral Spiral Porcupine Rod over bend Corrugated Looped Supports Ceramic tubes Grooves Ceramic tubes Metallic rods Metallic staples Ceramic tubes Material Sillimanite Chamotte grade 28 Sillimanite Kanthal® APM U-shaped Kanthal® nails Sillimanite Max.

Operating life and maximum permissible temperature

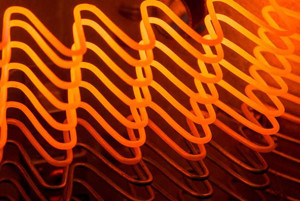

When heated, resistance heating alloys form an oxide layer on their surface, which prevents further oxidation of the material. To accomplish this function the oxide layer must be dense and resist the diffusion of gasses. It must also be thin and adhere to the metal under temperature

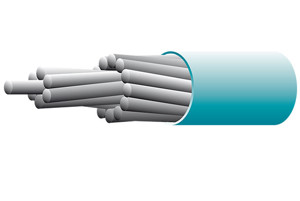

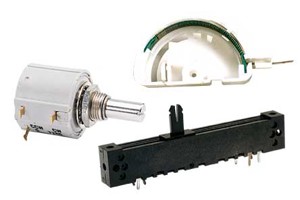

Stranded resistance heating wire

Recognizing the need for more precisely controlled stranded wire within the heat treatment industry and working closely with our cable customers, Kanthal has developed a range of stranded resistance wires in the well known Nikrothal®, Kanthal® and nickel alloys. Content: Strand diameter

Copper-nickel alloys

COPPER-NICKEL (CuNi) ALLOYS Copper-nickel (CuNi) alloy Cuprothal® 49 (universally known as Constantan) is manufactured under controlled conditions from electrolytic copper and pure nickel. Cuprothal® 49 has a number of special characteristics – some electrical, some mechanical – which

Nickel-iron alloys

NICKEL-IRON (NiFe) ALLOYS Nickel-iron (NiFe) alloys for up to 600°C (1110°F): Nifethal® 70 and Nifethal® 52 are alloys with low resistivity and high temperature coefficient of resistance. The positive temperature coefficient allows heating elements to reduce power as temperature

Austenitic alloys

Austenitic alloys AUSTENITIC (NiCr) ALLOYS Nickel-chrome (NiCr) alloys possess high mechanical strength that is maintained even at elevated temperatures, making them ideal for use as heat-resistant materials in various industrial processes. Kanthal’s range of NiCr alloy products,

Ferritic alloys

FERRITIC (FeCrAl) ALLOYS These alloys are known for their high electrical resistivity and exceptional resistance to hightemperature oxidation, making them ideal for use as electric heating elements and resistance materials in electronic equipment. Our range of FeCrAl alloys, branded

Kanthal GmbH - Once again awarded the audit berufundfamilie certificate

Kanthal GmbH awarded the audit berundfamilie certificate for its sustainable human resources policy.

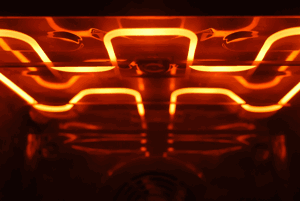

Furnace systems for custom processes

Custom large-scale split shell high temperature heating systems for a variety of material processing applications, featuring typical operating temperatures up to 1200°C (2192°F). The rotary system’s modular design allows for fast adaptation to varied sizes, with typical sizes of 18 meter