Cerca

634 risultati

634 risultati per "tutte le pagine" in intero sito Web

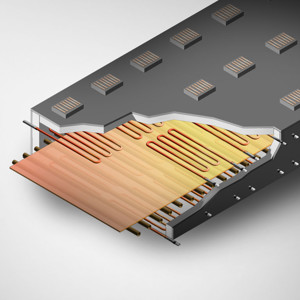

Preriscaldo degli anodi

Il passaggio dal riscaldo a gas a quello elettrico nei forni per il preriscaldo dell’anodo può avere importanti impatti positivi sul costo della produzione di alluminio primario.

Essiccazione della siviera

L'impiego degli elementi riscaldanti Kanthal® Super e dei moduli riscaldanti Superthal® permette di controllare efficacemente l'asciugatura della siviera, garantendo un processo uniforme durante la lavorazione di anodi e catodi.

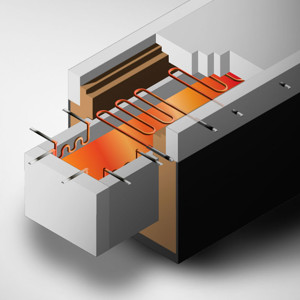

Reparti Rodding

Il passaggio dal riscaldo a gas a quello elettrico nella lavorazione di anodi e catodi nei nostri reparti rodding può supportare l'elevata necessità di questa industria di una riduzione dei costi energetici e delle emissioni di CO2.

Shunt

I materiali Kanthal per shunt ridefiniscono la precisione elettronica, offrendo resistenza su misura, tolleranza stretta e affidabilità senza pari.

Come il riscaldo elettrico può aiutare i produttori di schiuma di vetro a raggiungere il loro pieno potenziale

Impiegando materiali riciclati ed un processo rispettoso dell'ambiente, il processo di produzione del schiuma di vetro contribuisce a un mondo più sostenibile.

Trovare la giusta soluzione di riscaldo per i forni da tempra del vetro

Nel processo di tempra del vetro, è essenziale il controllo della temperatura nelle diverse zone di riscaldo del forno sia accurato. Kanthal offre soluzioni che garantiscono un riscaldo preciso e affidabile.

Perché i canalidi alimentazione (feeder) stanno tornando al riscaldo elettrico

Con decenni di esperienza negli elementi riscaldanti per feeder, Kanthal propone una soluzione che garantisce una maggiore efficienza e un controllo della temperatura più efficace.

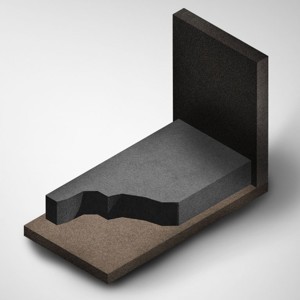

Schiuma di vetro

Con la sua attenzione nel riciclaggio del vetro e sulla sua trasformazione in materiale isolante, l’industria della schiuma di vetro è già sulla strada giusta. Tuttavia, le emissioni di CO2 sono importanti a causa dell'uso comune di bruciatori a gas che offrono una scarsa efficienza

Vetro per contenitori

Che si tratti di riscaldo elettrico su misura per forni di ricottura o forni a canale, i sistemi di riscaldo Kanthal offrono un controllo superiore della temperatura, un ridotto impatto ambirntale ed un'efficienza senza pari. E con i prezzi del gas che hanno raggiunto livelli elevati,