Search

633 hits

633 hits on ”all pages” in entire website

How Atmospheric Processes Shape High-Performance Semiconductor Devices

Atmospheric processes in semiconductor manufacturing shape high-performance devices by controlling oxidation, annealing, and high-temperature drive for tailored characteristics.

Horizontal and vertical diffusion cassettes

Semiconductor furnaces use "horizontal" or "vertical" orientation based on wafer size, automation level, and process requirements for optimal manufacturing.

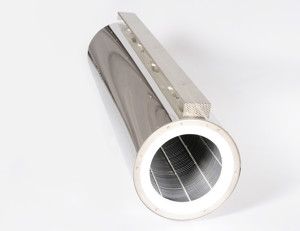

Heavy gauge diffusion cassettes

Heavy gauge cassettes featuring larger gauge resistance wire hot-formed into cylindrical shapes offer consistent and reliable heating with varying zones for applications up to 1,300°C (2372°F).

Light gauge diffusion cassettes

Light gauge cassettes, with thin wire sinusoidal patterns, are essential for precise diffusion in semiconductor manufacturing, ideal for low-temperature processes and rapid thermal changes.

Fibrothal® diffusion cassettes

Diffusion cassettes securely hold wafers during semiconductor manufacturing, facilitating precise dopant introduction and temperature/time control.

Ceba and Kanthal in strategic partnership for the green shift – focus on electric ladle and tundish preheaters

A new strategic partnership between Kanthal, a global leader in industrial heating technology, and CEBA, an expert in equipment for ladle and tundish preheating and drying, aims to offer sustainable electric solutions for advancing the green technology shift.

Tundish preheating

Optimize tundish preheating with Kanthal's electric heating solutions. Ensure precise temperature control, reduced emissions, and enhanced safety for more efficient and sustainable steel production.

Ladle preheating

Kanthal electric heating elements for ladle preheating deliver precise temperature control, reduced emissions, and increased efficiency. Upgrade to a safer and cleaner solution for steel production.

Nicolai Schaaf: Leading sustainability efforts at Kanthal

As the driving force behind Kanthal's sustainability initiatives, Nicolai Schaaf’s role is instrumental in reducing the company’s environmental impact and enhancing its economic performance.

Strong demand for electric heating makes Kanthal expand its silicon carbide production capacity

Kanthal expands its silicon carbide production capacity due to strong demand for electric heating