Search

633 hits

633 hits on ”all pages” in entire website

Strip

Content: Kanthal® A-1 Kanthal® AF Kanthal® APM Kanthal® APMT Kanthal® D Nikrothal® 80 Nikrothal® 70 Niktrothal® 60 Nikrothal® 40 Kanthal® A-1 Resistivity 1.45 Ω mm2/m Density 7.1 g/cm3 To obtain resistivity at working temperature, multiply by factor

Ribbon

Content: Kanthal® A, Kanthal® AF and Kanthal® AE Kanthal® D Alkrothal® Nikrothal® 80, Nikrothal® 60 and Nikrothal® 40 Cuprothal® 49 Kanthal® A, Kanthal® AF and Kanthal® AE Ribbon dimensions and properties Resistivity 1.39 Ω mm2/m (836 Ω/cmf).

Wire

Content: Kanthal® A-1 Kanthal® AF Kantal® APM Kanthal® APMT Kanthal® D Nikrothal® 80 Nikrothal® 70 Nikrothal® 60 Nikrothal® 40 Kanthal® A-1 Resistivity 1.45 Ω mm2/m Density 7.10 g /cm3 To obtain resistivity at working temperature, multiply by factor

Product varieties

Rod Wire Strip Ribbon Welded tubes Extruded tubes Straightened wire Kanthal® APM • • • • • Kanthal® A-1 • • • • Kanthal® A • • • Kanthal® D • • • • • Kanthal® DT • • • • • Kanthal® AF • • • • • Kanthal® AE • • • Alkrothal® • • • • • Nikrothal® 80 • •

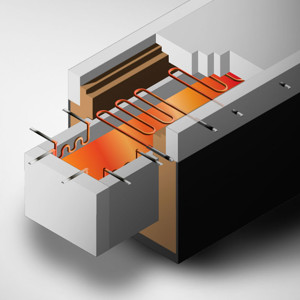

How to form a strip heating element

Welcome into our element workshop where we meet Stephen Smee and Kanthal material expert, Torbjörn Frankén. Together they walk us through how to form a Kanthal AF strip element, what to think about and what to watch out for. For more “How to” videos, follow our YouTube channel. In short:How electric heating can help foam glass manufacturers reach their full potential

With recycled materials and an environmentally friendly process, the foam glass manufacturing process contributes to a more sustainable world.

Why heating is key to producing high-quality optical fiber cables

Sintering of optical fibers is crucial since the fiber optic cables need to be developed with a specific refractive index to be able to transmit wavelengths.

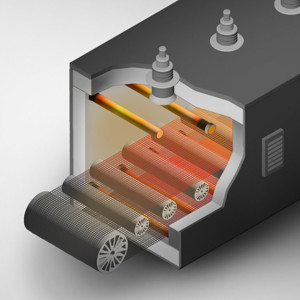

Gas or electric: which is best for glass annealing lehrs?

Using electric heating instead of traditional gas, controlled temperature and even distribution is achieved after the forming process of glass annealing lehrs.

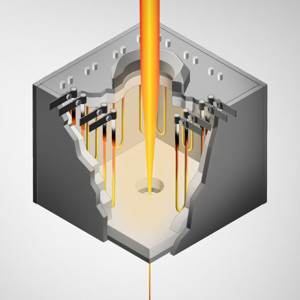

Why forehearth furnaces are returning to electric heating

Kanthal’s Globar® SiC elements improve efficiency, temperature control, and sustainability in forehearth furnaces, reducing emissions and enhancing glass quality.

Container glass

Kanthal’s electric heating solutions for forehearth furnaces and annealing lehrs offer superior temperature control and efficiency in container glass production.