Search

633 hits

633 hits on ”all pages” in entire website

How to weld a metallic heating element

Welding is an excellent way to increase efficiency, improve forming and strengthen your heating elements. But there is lots to consider for element welding; from which material to use for terminals, to how to weld terminals onto the metallic elements. In this video, our welding expert ChristerEverything you need to know about electric furnace maintenance

Do electric furnaces need maintenance? Although minimal, yes indeed, and there are a few key things to think about. Together with Stephen Smee, our material expert Torbjörn walks us through everything you need to know about how to service an electric furnace to keep it hot and well for as longHow to form a coiled heating element

Are you curious to know how to make a coiled heating element, why nichrome is non-magnetic, or why the same heating wire can have different color? Welcome into our element workshop where we meet Stephen Smee and Kanthal material expert, Torbjörn Frankén who walk us through everything youOptical fibers

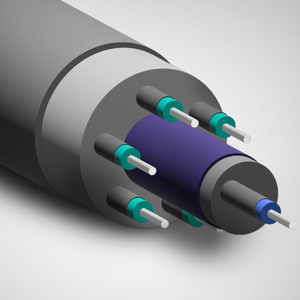

In the manufacturing of optical fiber, sintering is a key process where the heating solution utilized affects the quality of the end product. This is because sintering is done in a controlled atmosphere and having precise control over the heat input and temperature, which Kanthal’s electric

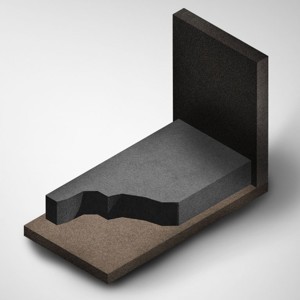

Foam glass

With its focus on recycling glass and turning it into insulation, the foam glass industry is already on the right path. Still, CO2 emissions are prominent because of the common use of gas burners which offers poor thermal efficiency at around 30 percent – compared to 90 percent thermal

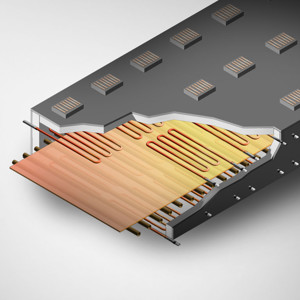

Finding the right heating solution for glass tempering furnaces

For glass tempering furnaces, temperature control over different heating zones is crucial, and Kanthal can deliver solutions for precise heat and reliability.

Kanthal and Rath announce strategic partnership to expand sustainable industrial heating technology offerings

Kanthal and Rath announces the signing of a strategic partnership to expand sustainable heating offerings in the market.

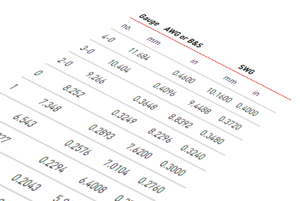

Miscellaneous conversion factors

Miscellaneous conversion factors To convert from To Multiply by BTU Kilo-calorie 0.25200 BTU Foot-pound 778.17 BTU Joules 1054.0 BTU Kilowatt-hour 0.00029307 Calorie Joule 4.1840 Centigrade Fahrenheit (1.8 x °C) + 32 Circular mil Square centimeter 0.000005067 Circular mil Square inch

Symbols, formulas and definitions

List of symbols Unit for calculations Symbol Meaning Metric Imperial Ac Surface area of heating conductor cm2 in2 b Width (ribbon or strip) mm in Ct Temperature factor (ratio of resistivity at operating temperature to resistivity at room temperature) d Wire diameter mm

Terminals (resistance and weight data)

Kanthal® A-1 and Kanthal® APM Dimension, mm Resistance, Ω/m Weight, g/m 8 0.0288 357 10 0.0185 558 12 0.0128 803 16 0.0072 1428 20 (Kanthal® APM only) 0.0046 2231 30 (Kanthal® A-1 only) 0.0021 5019 39 (Kanthal® APM only) 0.0012 8922 Kanthal® D Dimension, mm Resistance,