Search

633 hits

633 hits on ”all pages” in entire website

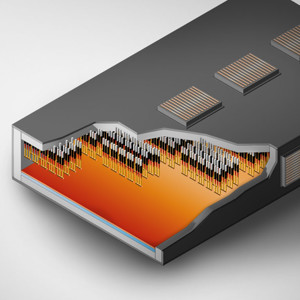

Long life heating elements for long-life float baths

To achieve an exceptionally smooth finish on flat glass, the float bath process is a necessary step in flat glass manufacturing.

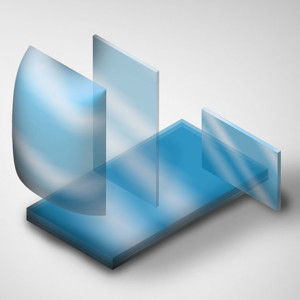

Keep production flowing in fusion-manufactured display glass

Explore Kanthal's fusion display glass solutions for high-quality flat glass manufacturing and advanced display technology.

Flat glass

With flat glass, precise temperature control, heating element longevity and reliability are key factors when choosing the appropriate type of heating elements. Kanthal’s electric heating offer provides this, and with it comes a more quiet and clean work environment with significantly lower CO2

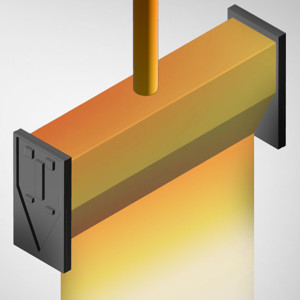

Element support systems

Content: Wire: Spirals - free radiating Wire: Spirals Wire: Rob Wire: Loop Strip: Corrugated - free radiating Strip: Corrugated USE OF CERAMIC SUPPORT MATERIALS The ceramics used in furnace construction significantly affect furnace life, operating properties, and thermal efficiency.

Elements in furnaces

For determining the dimensions and forms of industrial elements, the main factors are furnace temperature, furnace power (which depends on the load and the heating rate), available voltage, and the physical size of the furnace chamber. These are discussed below. Furnace temperature

Elements for electric appliances

Elements for electric appliances can be grouped in various ways. If classified according to how the wire is mechanically supported, they can be divided into three groups: embedded, supported, and suspended elements. Content: Element types Overview: Appliance element types Element

Linda Widigsson about leadership and career choices

Linda Widigsson, Kanthals CFO, is on this year’s prestigious mining and steel industry list ”40 over 40”. The achievements are results of a career based on taking on fun and interesting roles.

Delivery forms - Kanthal®, Alkrothal® and Nikrothal®

To prevent transport damage, all goods are securely packed in either cardboard boxes or wooden cases, with appropriate internal protection. Resistance heating alloys are available in a variety of delivery forms, including wire spools, pails, coils, and strips, to cater to diverse

Standard tolerances

Standard tolerances for wire are provided below. Size tolerances do not apply to material manufactured to resistance tolerances and vice versa. Tolerances on electrical resistance Resistance of Wire at 20°C (68°F) Diameter ≤ 0.127 mm (0.005 in): ± 8% All dimensions > 0.127 mm (0.005