Pesquisar

634 acessos

634 resultado para "todas as páginas" em em todo o site

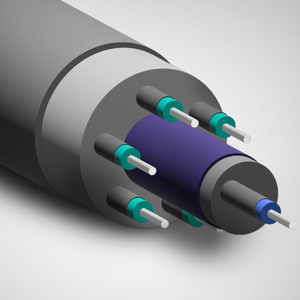

Fibras ópticas

Na fabricação de fibra óptica, a sinterização é um processo fundamental onde a solução de aquecimento utilizada afeta a qualidade do produto final. Isso ocorre porque a sinterização é feita em atmosfera controlada e ter controle preciso sobre

Vidro para contêineres

Quer se trate de aquecimento elétrico adaptado para fornos de recozimento ou fornos de antecâmara, os sistemas de aquecimento elétrico da Kanthal oferecem controle de temperatura superior, pegada de carbono reduzida e eficiência incomparável. E com os preços do gás

Forno de retenção e misturador

A substituição de aquecedores a gás por aquecimento elétrico em fornos de retenção e misturadores pode reduzir significativamente os custos e tornar o processo muito mais limpo e silencioso.

Pré-aquecimento de ânodo

Passar do aquecimento a gás para o aquecimento elétrico em fornos para pré-aquecimento anódico pode ter impactos positivos significativos no custo da produção de alumínio primário.

Secagem do cadinho

Usando elementos de aquecimento Kanthal® Super e módulos de aquecimento Superthal®, a secagem da panela pode ser controlada, permitindo uma experiência de secagem consistente no processamento de ânodo e cátodo.

Área de lingotamento

A mudança do aquecimento a gás para o aquecimento eléctrico no processamento de ânodos e cátodos em oficinas de rodding pode ajudar a procura em toda a indústria por custos de energia e emissões de CO2 mais baixos

Shunts

Os materiais dos resistores da Kanthal redefinem a precisão eletrônica, oferecendo resistência personalizada, tolerância apertada e confiabilidade incomparável.

How Kanthal plans to uphold its leadership in electric industrial heating

Learn how Kanthal aims to sustain its leadership in electric industrial heating with innovation, digitalization, and a customer-centric approach.

Kanthal revamps industrial gas heating with Prothal® portfolio

Kanthal's Prothal® portfolio aims to change the landscape of industrial process gas heating with innovative, efficient, and sustainable electric solutions.Kanthal and Danieli announce strategic partnership

Kanthal, a world leader in electric industrial heating technology, and Danieli, a major global supplier of turnkey plants and equipment for the iron- and steel industry, have announced a strategic partnership to jointly scale up Kanthal’s demonstrated electric process gas direct-heating